1) PACKAGING

1.1) INTRODUCTION

Packaging means wrapping, compressing, filling or creating of goods for the purpose of protection of goods and their convenient handling.

Packaging is an important part of the product, which has to receive a lot of attention to the people. It is concerned with designing & producing of appropriate packages for a product. Packaging also refers to the process of design, evaluation, and production of packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end.

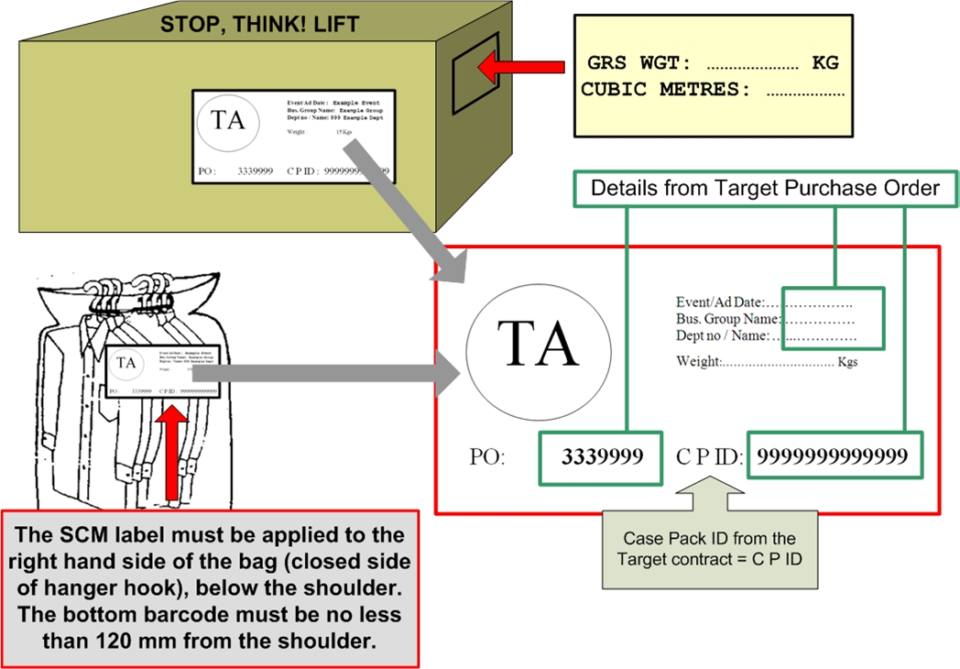

After final inspection & garments folding, the garments are poly-packed dozen-wise, color wise, size ratio wise, bundled and packed in the carton. The carton is marked with important information in printed form which is seen from outside the carton easily. Specially, it is needed to ensure the placement of sticker in proper place.

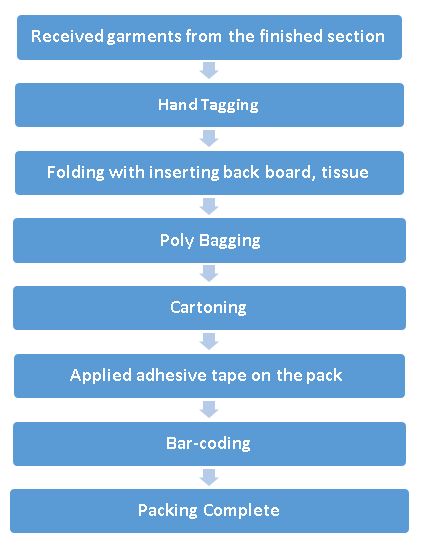

1.2) Flow Chart Of Garment Packaging

1.3) Apparel Packaging Sequence

- After folding garments are packed in polyethylene packets

- Generally polyethylene packets are of different sizes

- During packing, the position of sticker and other label should be confirmed

- After polyethylene packing , garments are kept in the sorting rack according size and color

- Then garments placed in inner box from the sorting rack according to size and color

- Packing in inner box according to work order is called is called ‘assortment’

- The packing that is done by the fixed no. of inner box in the cartoon is called cartoning or packing

- The carton is sealed with the scotch tape

- Carton bears some information on it g. carton box no. carton box size, shipping mark, destination etc.

1.4) Classification of Packaging

1.5) Based on Garment Packaging:

Different types of packaging are there for different types of garments. Following is the most used packing types –

- Stand up pack: Shirt (90° angle)

- Flat pack: Sport wear/Shirt/Trouser

- Hanger pack: Blazer, Coats, Pants

- Semi stand up pack: Shirt

- Half fold pack: Pant

1.6) Packaging Design

1.6.1) Merchandising packaging

The merchandise package is the unit the consumer receives when he selects the product. What functions must a merchandising package perform in order to stimulate sales of the product in the package? From the consumers point of view the merchandise package should :

- Identify the product

- Enhance the appeal of the product

- Attract the consumer to the package

- Protect the product quality until the consumer uses the item

Transparent plastic film is useful in meeting all of the requirements. Seeing the product makes it easy to identify and attract the consumer. Colour and design on the package are other ingredients that are used to identify, enhance and attract. The manner in which the product is packaged geometrically is a big factor in enhancing the appeal of the garment. The utility of the package is a big factor in attracting the consumers. The artistic value of a package is another persuader which attracts consumer.

1.6.2) Vacuum Packaging

The function of a vacuum packaging is:

- To reduce the shipping bulk of unfinished garments

- To reduce the shipping weight of garments shipped

- To prevent a garment from accumulating dust or objectionable odours before and during shipping

- To prevent garments from acquiring wrinkles or creases, during shipping, this will have to be removed before the retailer displays the garments

- To minimize storage space for both the manufacturer and retailer

Vacuum packaging is used not only for packing and storing garments, but also for packaging household accessories made from textiles, such as blankets, bedspreads, pillows and towels-anything with bulk that can be easily compressed.

Vacuum packaging was introduced in the 1970s by Swematex AB, of Ganghester, Sweden. (Rheemes Textile Systems, Inc., New York City, is the U.S. licensee for this equipment.) The system consists of:

- Reducing the moisture content of the garment;

- Encasing the garment in a plastic film sack; after which

- The air in the sack and garment are vacuumed out as the garment is compressed within

- Which is sealed at the end of the vacuum and compression cycle.

The moisture content is removed by passing the hung garment on a conveyor through a conditioning chamber which decreases the moisture content of the garment with hot dry.

1.6.3) Shipment Packaging

The shipment package performs the distributors function. It is the package the carrier receives and delivers to the retailer. It delivers the merchandise package to the retailer (or the wholesaler).

Shipping packing’s may be divided into the classes with respect to the protection from

- Closed containers carrying garments

- covered completely individually by a merchandising package (closed merchandising packages)

- without a covering merchandising package (an open merchandising package)

- Open containers carrying garments

- In closed merchandising packages,

- In open merchandising packages.

Costs, suits, or dresses transported without individual covers on hangers, suspended from portable hanger racks, are examples of open merchandising packages carried in open containers. Cartons with hanger racks. “Hanger Pac”, are examples of closed containers designed to carry the garments in open or closed merchandising packages. In fact, any shipping packages can carry open or closed merchandising packages.

In order to protect and preserve the merchandise package and its garment during the distribution process, the shipping package can be designed to do the following:

- Fusion, (2) separate, (3) brace, and (4) ward for water and dirt. A shipping package is proper when it prevents normal loads and pressures exerted on it, during the distribution process, from damaging the merchandise package or its garments.

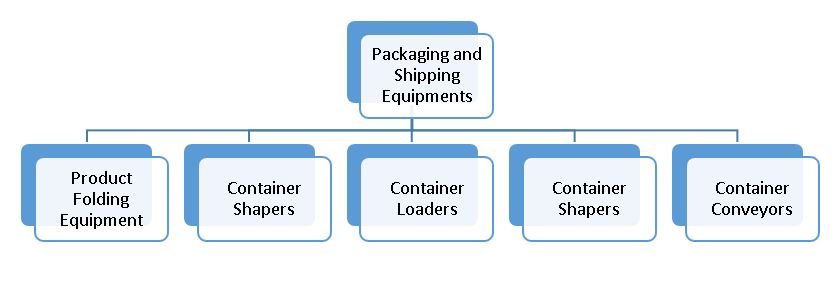

1.7) Packaging and Shipping Equipment

1.8) Packaging Materials

- Plastic clip

- Paper board

- Wooden Boxes and Crates

- Butterfly

- Plastic collar

- Tag pin

- Ball head pin

- Poly bag

- Inner box

- Tissue paper

- Carton

- Scotch tape

1.9) FUNCTIONS OF PACKAGING

The various functions of packaging are divided into primary, secondary and tertiary functions.

In contrast with the primary functions, which primarily concern the technical nature of the packaging, secondary functions relate to communications.

Primary, secondary and tertiary functions are divided into the following sub-functions

1.9.1) PRIMARY FUNCTIONS

- Protective function

The protective function of packaging essentially involves protecting the contents from the environment and vice versa. The inward protective function is intended to ensure full retention of the utility value of the packaged goods. The packaging is thus intended to protect the goods from loss, damage and theft.

In addition, packaging must also reliably be able to withstand the many different static and dynamic forces to which it is subjected during transport, handling and storage operations. The goods frequently also require protection from climatic conditions, such as temperature, humidity, precipitation and solar radiation, which may require “inward packaging measures” in addition to any “outward packaging measures”.

The outward protection provided by the packaging must prevent any environmental degradation by the goods. This requirement is of particular significance in the transport of hazardous materials, with protection of humans being of primary importance. The packaging must furthermore as far as possible prevent any contamination, damage or other negative impact upon the environment and other goods.

The inward and outward protective function primarily places demands upon the strength, resistance and leak proof properties of transport packaging.

- Storage function

The packaging materials and packaging containers required for producing packages must be stored in many different locations both before packaging of the goods and once the package contents have been used. Packaging must thus also fulfill a storage function. - Loading and transport function

Convenient goods handling entails designing transport packaging in such a manner that it may be held, lifted, moved, set down and stowed easily, efficiently and safely. Packaging thus has a crucial impact on the efficiency of transport, handling and storage of goods. Packaging should therefore be designed to be easily handled and to permit space-saving storage and stowage. The shape and strength of packages should be such that they may not only be stowed side by side leaving virtually no voids but may also be stowed safely one above the other.

The most efficient method of handling general cargo is to make up cargo units. Packaging should thus always facilitate the formation of cargo units; package dimensions and the masses to be accommodated should where possible be tailored to the dimensions and load-carrying capacity of standard pallets and containers.

Where handling is to be entirely or partially manual, packages must be easy to pick up and must be of a suitably low mass. Heavy goods must be accommodated in packages which are well suited to mechanical handling. Such items of cargo must be forkliftable and be provided with convenient load-bearing lifting points for the lifting gear, with the points being specially marked where necessary (handling marks).

The loading and transport function places requirements upon the external shape of the package, upon the mass of the goods accommodated inside and upon the convenient use of packaging aids. The strength of the package required for stowing goods on top of each other demonstrates the close relationship between the loading and transport function and the protective function.

1.9.2) SECONDARY FUNCTIONS

- Sales function

The purpose of the sales function of a package is to enable or promote the sales process and to make it more efficient. - Promotional function

Promotional material placed on the packaging is intended to attract the potential purchaser’s attention and to have a positive impact upon the purchasing decision. Promotional material on packaging plays a particularly important role on sales packaging as it is directly addressed to the consumer. This function is of subordinate significance in transport packaging. While product awareness is indeed generated along the transport chain, excessive promotion also increases the risk of theft. - Service function

The various items of information printed on packaging provide the consumer with details about the contents and use of the particular product. Examples are the nutritional details on yogurt pots or dosage information on medicines.

The package may also perform a further function once the contents have been used (e.g. storage container, toy).

- Guarantee funcion

By supplying an undamaged and unblemished package, the manufacturer guarantees that the details on the packaging correspond to the contents. The packaging is therefore the basis for branded goods, consumer protection and product liability. There are legislative requirements which demand that goods be clearly marked with details indicating their nature, composition, weight, quantity and storage life.

1.9.3) TERTIARY FUNCTIONS

- Additional function

The additional function in particular relates to the extent to which the packaging materials or packaging containers may be reused once the package contents have been used. The most significant example is the recycling of paper, paperboard and cardboard packaging as waste paper.

1.10) CARTON PACKAGING

After packing, cartoning is done according to apparel size and color. Most used packing types are given below:

- Solid color Solid size pack

- Solid color Assorted size pack

- Assorted color Solid size pack

- Assort color Assort size pack

Types of Cartons for Garment Packaging

- Depend on Paper

- Khaki Carton or Brown Paper

- Duplex Carton

- Box Carton

- Depend on Stitching

- Gum Plasting Carton

- Depend on Ply

- 3 ply Carton

- 5 ply Carton

- 7 ply Carton

- Depend on Liner

- Both Side Liner Carton

- Out Side Liner Carton

- Depend on Size

- Master Carton

- Inner Carton

Carton packing may be varying according to Buyer’s requirement. Carton pack may :

- 12pcs/Carton

- 24pcs/Carton

- 36pcs/Carton

1.11) AUTOMATIC PACKAGING MACHINES

- THERMOSOL PV38

- ACCUTECH Autofulfillment™ SPrint™ System

- Autobag AB 180

1.11.1) Autobag AB 180

- The Autobag AB 180 OneStep is uniquely designed to provide flexible solutions for dynamic packaging environments, such as mail order fulfillment, short production run, and build-on-demand operations

- By positioning the PI 412c imprinter directly over the next bag to be loaded, the AB 180 OneStep prints and indexes in a single-step – virtually eliminating bag waste and product queuing

1.11.2) THERMOSOL PV38

- The PV-38 is an automatic bagging machine for ready-made clothes

- The output capacity of PV38 depends on the output speed of STP-1000 or on how fast the operator places the clothes in the machine when the machine functions independently

1.11.3) ACCUTECH Autofulfillment™ SPrint™ System

- The Autofulfillment™ SPrint™ System is uniquely engineered to bring automation, speed and flexibility to high-volume mail order fulfillment applications.

- It is designed with advanced integration technology from Accutech Packaging and innovative product engineering from Automated Packaging Systems.

- The Autofulfillment SPrint System operates at speeds of 12 to 15 completed bags per minute.

- The system is designed to easily package single or multiple items in the same bag, while accurately scanning and verifying the complete contents of each order.

- Operational Benefits:

- Automates the order fulfillment process to increase productivity and reduce costs

- Modular and customizable components provide for flexible configurations and expansion for growth

- Easy to use operating system simplifies job changeovers

- Stabilizes and reduces labor requirements for both on- and off-peak seasons

- Multi-point verification ensures accuracy in single or multiple item orders

- Apparel / Sportswear

- Shoes

- Sporting Goods

- Automotive Parts

- Hardware/Plumbing

- Lawn & Garden

- Pet Supplies

- Printed Materials

1.12) Advancements in Packaging field in Garment Industry

Packaging machines for textile industry comes in precision design and latest technology so as to provide optimum functional support involved in packaging operations.

The use of advanced engineering concepts in these machines allows for achieving consistent output with very less downtime and maintenance cost. the film packaging machines offered for different textile products allows to handle the packaging needs of products like:

- Non-Woven fabrics

- Binder yarns

- Spools

- Textile Rolls

Process support is provided in form of automatic or semi-automatic case packers, sealers, loaders and other process units. In combination, these packaging systems offer supporting form of

- Shrink Wrapping

- Stretch Wrapping

- Spools

- Case Sealers

- Case Erectors

- Case Packers

2.12.1) Performance and Accuracy

Some of the standard features that balance the performance and accuracy parameters of these packaging machins include:

- Machines designed to offer competitive functional support

- The functional parameters of the machines can also be custom tuned as demanded by the customers

- User-friendly working interface for allowing easier handling of operations

1.12.2) Latest Technology Support

- Machines made available with automatic/semi-automatic operation support with presence of modular packaging heads for complete ease in packaging processes

- Machines designed to provide desired flexibility

- Machines designed to allow quick changes overs to handles products in different sizes and shapes

- Machines deigned to also easy integrate in present textile processing line

1.13) Sustainable Packaging Options

- ECOLOGI:

- ECOLOGIis a globally responsible, innovative and sustainable shoe packaging solution

- It offers an eco-friendly approach to H&M’s packaging logistics

- ECOLOGI reflects the vision and core values of H&M, translating these values into three key points: planet, people and price

- H&M’s packaging solution are eco-conscious, human-centered and cost-conscious

- It offers one complete solution for maximum social impact

- RSC Shipping Boxes

- RSC Shipping Boxes are Globe Guard® 100% recycled content corrugated shipping boxes

- It is common for an application or product to be able to ship out in either a die cut mailer box or a Regular Slotted Container (RSC) style shipping container

- Both are quite effective and can be as eco friendly as the corrugated board that is used to make them

- RSC is less expensive because it consumes less board

- Natur-Tec®

- Natur-Tec® has engineered sustainable solutions for packaging of garment and consumer apparel

- These products are made from fully biodegradable and compostable materials that are environment friendly alternatives to conventional plastics such as polyethylene and polypropylene

- Natur-Tec products are manufactured from renewable/natural materials, and engineered to provide high level of performance and protection in a packaging application

- Applications:

- Garment bags

- Leather jacket/Suit covers

- Shoe bags and covers

- Hangers

- Shirt clips and buttons

2) FOLDING

1.1) Introduction

After completing pressing, the garments are folded with a predetermine area. Garments are folded according to the buyers direction, requirements in a standard area.

2.2) Folding of some Basic Garments:

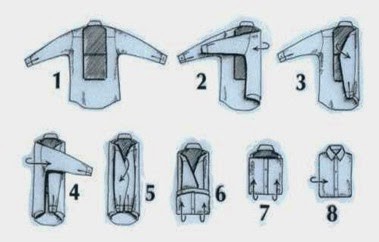

2.2.1) Folding of a basic Shirt

There are mainly 4 types available for folding shirt is given below-

- Stand up: Collar is folded with body and situated at 90 degree angle.

- Semi-stand up: Collar is folded with body and situated at 45 degree angle.

- Flat pack: Collar is spread as a whole on the body of shirt.

- Hanger pack: Shirt is packed and transported by hanging on the hanger. At the end of folding , garment are placed into a polythene packet, the size of polythene packet is permanent.

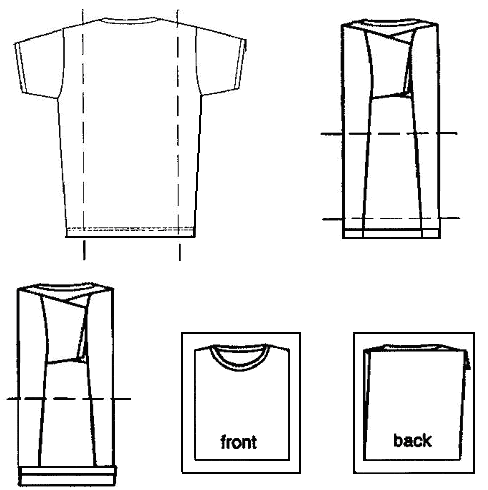

2.2.2) Folding of a Short-Sleeve T-shirt

- Fold the arms straight across back.

- Fold the shirt side seams across back of shirt.

- Fold the bottom edge of shirt about 2-inches from the bottom.

- Fold the shirt in half

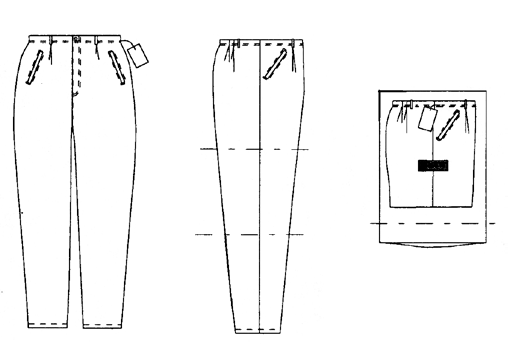

2.2.3) Pant folded side-to-side

- Close zipper and waist buttons.

- Fold pant in half, with inseam to out seam keeping ends of waistband to inside of pant.

- Fold leg in thirds – fold bottom edge to above knee and fold up to waist edge.

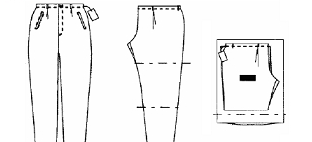

2.2.4) Pant folded front-to-back

- Close zipper and waist buttons.

- Fold pant front to back with fold at rise

- Fold leg in thirds – bottom edge to above knee and fold up to waist edge

2.3) Automatic Folding Machine

The automatic folding machine folds clothes quickly, silently and with precision. It functions independently and requires 1 operator. It is designed to fold t-shirts, sweatshirts, sweaters, undershirts, trousers, pants, etc.

It can be very easily adjusted for the various sizes and types of clothes so that the best desired folding is achieved.

The programs of the automatic folding machine are:

- Folding of a garment in half

- Single folding with a set length of the end folding

- Double folding with a set length of the end folding

- Double folding with a set length of the end folding (for very large garments)

Some of the most common Automatic Folding Machines used in the industries are:

- THERMOSOL STP-950

- THERMOSOL STP-1000

- THERMOSOL FX-23

2.3.1) THERMOSOL STP-950

- Especially designed for folding t-shirts perfectly

- Capacity: 5500 garments per 8 hrs.

- Technical Specifications

- Dimensions (L*W*H): 2540x1095x1510 mm

- Net weight: 328 kg

- Power supply: 400V/220V-50 Hz

- Power capacity: 35 KW

- Air pressure: 6 bar

- Air consumption: 28 NL/min

- Maximum output: 5 folding per minute

- Maximum garment dimensions (L&W): 100 cm & 85 cm (Trousers L=120 cm)

- Width of final folding: 160mm minimum & 320mm maximum

2.3.2) THERMOSOL STP- 1000

- Updated version of STP-950

- Especially designed for folding t-shirts perfectly

- Capacity: 5500 garments per 8 hrs.

- Technical Specifications

- Dimensions L(*W*H): 286*125*140cm

- Net weight: 335 kg

- Power supply: 400V/ 50-60 Hz

- Power capacity: 37 KW

- Air pressure: 6 bar

- Average Air consumption: 51 NL/min

- Maximum garment dimensions (L & W): 100cm & 80cm (Trousers L = 120cm)

- Width of final folding: 180mm minimum & 320mm maximum

2.3.3) THERMOSOL FX-23

- The FX-23, apart from the automatic folding, also offers two important options after the garment has been folded:

- The first optionis a program for stacking and easy gathering of the folded clothes

- The second optionis a program for easy packaging of the garment in a bag

- Maximum Output(Folding and Bagging): 2500 pieces per 8 hours

- Technical Specifications:

- Dimensions L*W*H: 1040x840x840 mm

- Net weight: 94 kg

- Power supply: DC 230V, 50-60 Hz

- Power capacity: 10 KW

- Air pressure: 6 bar

- Dimensions of folded garment:

- Width: 23 cm minimum & 30 cm maximum

- Length: 31 cm minimum & 37 cm maximum