Site selection or the location of a facility (service or manufacturing ) is finalizing on a location for constructing/expanding/acquiring a physical entity of the firm to better serve existing clients/enter into new markets or expand production capacity. it can be a warehouse, office, production facility, retail outlet, or franchise. All these will represent a physical node in the value chain. The site location is a crucial factor in delivering the goods and services in an effective manner to the market.

The site can be a new place or it can be in an existing facility where expansion can be carried out. It can be within the same country or can be on the opposite side of the globe. The final decision lies in the revenue generated by the site and the cost of running the facility. Site selection in some cases presents more risk than others as an office space its easier to decide but for a manufacturing facility, it will be more capital intensive and will require taking into account the local environmental law, labor law, and many more factors. Due to the complexities and risks presented by this step, it can take months to finalize a site for an organization.

Although site location is a strategic matter it is very much part of operations management because:-

- Operations management will be responsible for running the facility

- All day-to-day and long terms operations factors need to be considered as they can make or break a company:-

- Cost

- Stability in the region (financially, socially, politically, etc.)

- Skill availability

- supplier’s availability

- Other inputs such as energy/water/credit line/subsidies

- transport system

Kasra Ferdows, in Harvard Business Review, classifies foreign factories under six different categories:-

1. Offshore factory:- designed for specific products at low cost and targeted for exports. Little to no development or engineering is done at this facility.

2. Source factory:- This also aims at large-scale, low-cost production but has greater control over procurement, production planning, process planning, and design decisions.

3. server factory:- A server factory aims to take advantage of locations such as terrific waiver/reduced logistics/reduced taxes/reduced exposure to fluctuating currency and generally serves a specific targeted national or regional market.

4. Contributor factory:- The contributor factory is the same as the server factory with added responsibilities of product design/process engineering/supplier selection etc.

5. Outpost factory:- The outpost factory is located in a region where its primary role is to gather intelligence, market data, and other business-related information which can be used strategically by its parent firm. It is located near its competitors, R&D centers, and customers. It also undertakes production but only to justify its existence.

6. Lead factory:- Lead factory also sometimes known as the mother factory/flagship factory creates new processes, products and technologies for the entire company. It also undertakes most of the development and design works. The operations management here plays a crucial role in directing the whole supply chain of the company.

Key factors:

- Staffing:- it includes hiring all types of personnel (contract/full-time/trainee/direct/indirect/management etc.) for running a facility. sub factors of staffing are:-

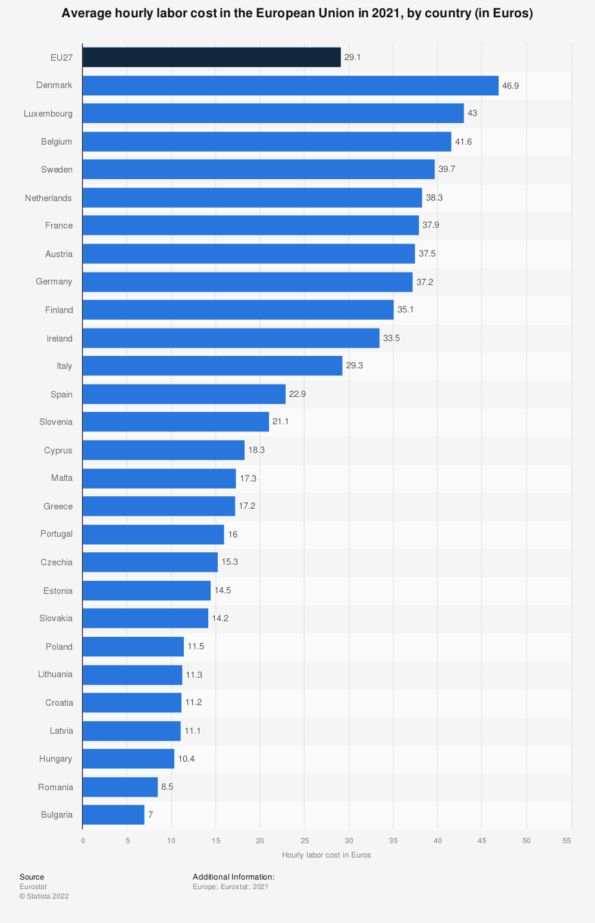

- Labor costs:- Direct wages are one of the most important criteria when performing site selection. This is why we see companies based out of the USA, Japan, and other developed economies having production facilities in developing countries where the wages are significantly lower. The higher wages will result in a higher final cost of the goods/services delivered.

- Social Charges:- These are additional charges which are indirectly related to welfare such as medical insurance, social security, paid vacations, retirement benefits, unemployment benefits, etc.

- Social laws:-This factor affects the cost in indirect ways such as working hour limitations, overtime, work week hiring, and termination laws.

- Availability of skilled labor:- Availability of trainable and unemployed labor plays a major role in site selection as based on the demand and supply rule, the higher the availability of unemployed labor, the lower will be staffing-related costs generally.

- Productivity:- The pool of talent available is how much productive and is a major decision variable in site selection. Labour in Asia is compared to more productive than labor in Africa and sometimes even in some eastern European countries. Learn more about different types of productivity here.

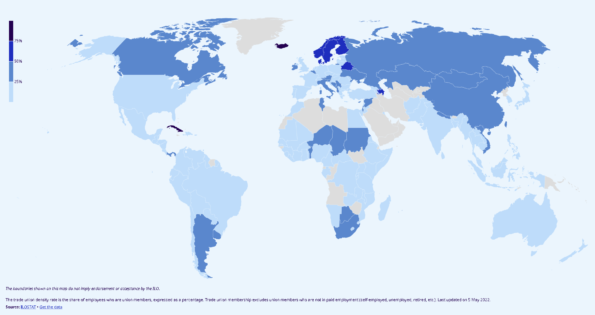

- Trade unions:- Strong trade unions are a big deterrent for any firm to locate in that region. On average trade union membership fell by 6.4% in OECD countries during 1980-1990.

Trade Union Map

Unions also lead to industrial actions (strikes) which result in lost productive days leading to missed deliveries and timelines for customer deliveries of goods and services.

- Education level:- The education level of the demography plays a crucial role as roles nowadays are becoming more technologically intensive. the existence of training institutes/colleges and other trade-related institutions helps to establish a constant supply of fresh talent who can perform the task effectively.

- Labor mix:- It states the mandatory local regulations that allow a mix of expatriate and local labor for operations/construction/management.

- Labor costs:- Direct wages are one of the most important criteria when performing site selection. This is why we see companies based out of the USA, Japan, and other developed economies having production facilities in developing countries where the wages are significantly lower. The higher wages will result in a higher final cost of the goods/services delivered.

- Inherent local conditions:- Local conditions such as climate, language, and culture plays an important role in the site selection. It impacts the operation in long run.

- Climate:- Good and contact weather conditions are favorable for operations. Moderate areas are always preferred in order to avoid the excess cost that will be required for heating/cooling/humidification/dehumidification or other activities.

- Culture:- The culture of the land can be sometimes difficult for expatriate employees to adapt thus resulting in higher premium salaries.

- Ethics:- Companies tend to avoid locations where their ethical principles are not matched. Such as many companies exited Russia after its invasion of Ukraine on Ethical and moral grounds.

- Language:- Companies prefer to extend operational bases in a place with the same language as either primary or secondary ones. It helps in easy communication in the value chain.