Method Study is the study of work (method) for a job to achieve process improvement, improve layout, improve design, better working environment, and reducing fatigue.

- Method study is more of a systematic approach to job design than a set of techniques

- It is defined as the systematic recording and critical examination of existing and proposed methods of doing work

- It is one of the keys to achieving productivity improvement in garment industry

- Method study is essentially used for finding better ways of doing work

- It is also a technique for cost reduction in garments manufacturing

Objectives of Method Study

- Improvement of processes and procedures

- Improvement in the design of plant and equipment

- Improvement of layout

- Improvement in the use of men, materials and machines

- Economy in human effort and reduction of unnecessary fatigue

- Improvement in safety standards

- Development of better working environment

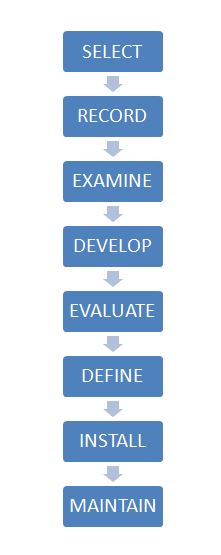

Method Study Flow Chart

These eight steps, constitute the logical procedure that a work-study specialist could normally apply. In practice, however, the procedure isnot as straightforward as it is presented here. For example, when measuring theresults achieved by the new method one may find that the resulting costeffectivenessmay be negligible and does not warrant the added investment intime and effort to develop the perceived method. In this case the work-study person may have to go back to the drawing board to examine the job oncemore and try to develop another improved method.

In other circumstances experience with a new improved method may bring to the surface new problems, in which case the process of examination,development and subsequent steps has to be repeated again.

Select

Work selected for method study may be an identified problem area or an identified opportunity. It may be identified through a systematic review of available data, normal monitoring or control processes, high levels of dissatisfaction and complaint or as part of a change in management policy, practice, technology or location, and usually because it meets certain conditions of urgency and/or priority.

Record

The Record stage of method study involves gathering sufficient data (in terms of both quality and quantity) to act as the basis of evaluation and examination. A wide range of techniques are available for recording; the choice depends on the nature of the investigation; the work being studied; and on the level of detail required. Many of the techniques are simple charts and diagrams, but these may be supplemented by photographic and video recording, and by computer based techniques.

Especially with “hard” (clearly defined) problems, method study often involves the construction and analysis of models, from simple charts and diagrams used to record and represent the situation to full, computerised simulations. Manipulation of and experimentation on the models leads to ideas for development.

Examine

Examining the way, the job is being performed and challenge its purpose, place, sequence and method of performance.

Evaluate

Evaluate different alternatives to develop a new improved method comparing the cost-effectiveness of the selected new method with the current method performance.

Define

Define a new method, as a result in a clear manner, and present it to those concerned, i.e. management, supervisors and workers.

Develop

The Examine stage merges into the Develop stage of the investigation as more thorough analysis leads automatically to identify areas of change. The aim here is to identify possible actions for improvement and to subject these to evaluation in order to develop a preferred solution.

Sometimes it is necessary to identify short-term and long-term solutions so that improvements can be made (relatively) immediately, while longer-term changes are implemented and come to fruition.

Install

The success of any method study project is realised when actual change is made ‘on the ground’ – change that meets the originally specified terms of reference for the project. Thus, the Install phase is very important. Making theoretical change is easy; making real change demands careful planning – and handling of the people involved in the situation under review. They may need reassuring, retraining and supporting through the acquisition of new skills. Install, in some cases, will require a parallel running of old and new systems, in others; it may need the build-up of buffer stocks, and other planning to manage the change. What matters is that the introduction of new working methods is successful.

Maintain

Sometime after the introduction of new working methods, it is necessary to check that the new method is working, that it is being properly followed, and that it has brought about the desired results. This is the Maintain phase. Method drift is common – when people either revert to old ways of working, or introduce new changes. Some of these may be helpful and should formally be incorporated; others may be inefficient or unsafe. A methods audit can be used to formally compare practice with the defined method and identify such irregularities.

Symbols Used in Method Study

Graphical method of recording was originated by Gilberth, in order to make the presentation of the facts clearly without any ambiguity and to enable to grasp them quickly and clearly. It is useful to use symbols instead of written description.

Method study symbols:

- Operation

- Inspection

- Transportation

- Delay

- Storage

Operation

An operation occurs when an object is intentionally changed in one or more of its characteristics (physical or chemical). This indicates the main steps in a process, method or procedure. An operation always takes the object one stage ahead towards completion.

An operation occurs when an object is intentionally changed in one or more of its characteristics (physical or chemical). This indicates the main steps in a process, method or procedure. An operation always takes the object one stage ahead towards completion.

Examples of operation are:

- Turning, drilling, milling, etc.

- A chemicalreaction

- Welding, brazing and riveting

- Lifting, loading, unloading

- Getting instructions from supervisor

- Taking dictation

Inspection

An inspection occurs when an object is examined and compared with standard for quality and quantity.

An inspection occurs when an object is examined and compared with standard for quality and quantity.

The inspection examples are:

- Visualobservations for finish

- Count of quantity of incoming material

- Checking the dimensions

Transportation

A transport indicates the movement of workers, materials or equipment from one place to another.

A transport indicates the movement of workers, materials or equipment from one place to another.

Example:

- Movement of materials from one work station to another

- Workers travelling to bring tools

Delay (Temporary Storage)

A delay occurs when the immediate performance of the next planned thing does not take place.

A delay occurs when the immediate performance of the next planned thing does not take place.

Example:

- Work waiting between consecutiveoperations

- Workers waiting at toolcribs

- Operators waiting for instructions from supervisor

Storage

Storage occurs when the object is kept in an authorized custody and is protected against unauthorized removal.

For example, materials kept in stores to be distributed to various work

Scope Of Method Syudy:

The task of work simplification and compatible work system design concerns the followings:

- Layout of shop floor and working areas or work stations

- Working conditions i.e. Ergonomics etc

- Handling distances (material movement)

- Tooling and equipment used

- Quality standards to be achieved

- Operators and operations in achieving the production targets

- Materials to be used

- Power required and available

- Work cycle time

- Working processes

- Economy in human effort and reduction of unnecessary fatigue

- Improvement in safety standards and procedures

- Development of better working environment

CONSIDERATIONS FOR SELECTION OF METHOD STUDY

The job should be selected for the method study based upon the following considerations:

1. Economic Aspects:

The method study involves cost and time. If sufficient returns are not attained, the whole exercise will go waste. Thus, the money spent should be justified by the savings from it. The following guidelines can be used for selecting a job:

- Bottleneckoperations which are holding up other production

- Operationsinvolving excessive labor

- Operationsproducing lot of scrap or defectives

- Operationshaving poor utilization of resources

- Backtracking of materials and excessive movement of materials

2. Technical Aspects:

The method study man shouldbe careful enough to select a job in which he has the technical knowledge and expertise. A person selecting a job in his area of expertise is going to do full justice.

Other factors which favor selection in technical aspect are:

- Job having in consistent quality

- Operationsgenerating lot of scraps

- Frequent complaints from workers regarding the job

3. Human Considerations:

Method study means a change as it is going to affect the way in which the job is done presently and is not fully accepted by workman and the union. Human considerations play a vital role in method study. These are some of thesituations where human aspect should be given due importance:

- Workers complaining about unnecessary and tiring work

- More frequency of accidents

- Inconsistent ear

An Article By:

National Institute of Fashion Technology