The Left and Right Hand Chart is a process chart in which the activities of a worker’s hands (or limbs) are recorded in their relationship to one another. It is a specialized form of process chart because it shows the two hands (and sometimes the feet) of the operative moving or static in relation to one another, usually in relation to a time scale. One advantage of incorporating a time scale in the chart form is that the symbols for what the two hands are doing at any given moment are brought opposite each other.

The two-handed process chart is generally used for repetitive operations, when one complete cycle of the work is to be recorded. Recording is carried out in more detail than is normal on flow process charts. What may be shown as a single operation on a flow process chart may be broken down into a number of elemental activities which together make up the operation.

Objectives:

- The very act of making this chart enables the work study specialist to gain an intimate knowledge of the details of the job and study each element of the job

- the relationships between two different activities can be established

- The aim of this chart is to eliminate or reduce the unwanted motion to minimum

- Give ideas for improvements and to arrange the best of motions in a possible sequence

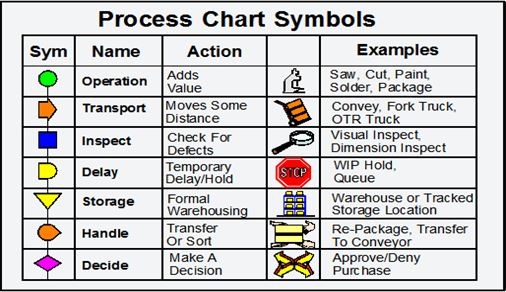

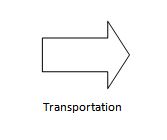

Symbols Used:

The left and right hand chart is generally used for repetitive operations, when one complete cycle of the work will be recorded. Recording is carried out in more detail than is normally used on flow process charts. What may be shown as a single operation on a flow process chart may be broken down into a number of elemental activities which together make up the operation. The two-handed process chart generally employs the same symbols as the other process charts but because of the greater detail covered the symbols are accorded slightly different meanings.

Following are the basic symbols used for left and right hand chart:

Following are the mainly used symbols in left and right hand chart:

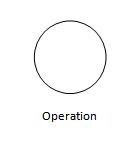

1. Operation

- An operation takes place when there is a change in physical or chemical characteristics of an object. An assembly or disassembly is also an operation.

- This symbol is used for is used for the activities of grasp, position, use, release, etc. of a tool, component or material.

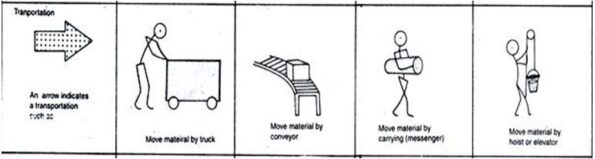

2. Transport

- This refers to the movement of an object or operator or equipment from one place to another.

- When the movement takes place during an operation, it is not called transport.

- Example: Moving the material by a trolley Operator going to the stores to get some tool.

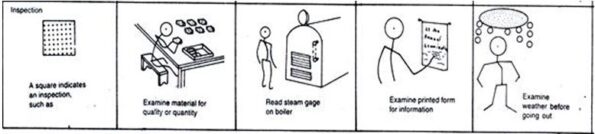

3. Inspection

- Inspection is checking an object for its quality, quantity or identifications.

- Example: Checking the diameter of a rod. Counting the number of products produced etc.

- The symbol for inspection is not much used because the hand movements when inspecting an article (holding it and examining it visually or gauging it) may be classified as “operations” on the two-handed chart. It may, however, sometimes be useful to employ the “inspection” symbol to draw attention to the examination of a piece.

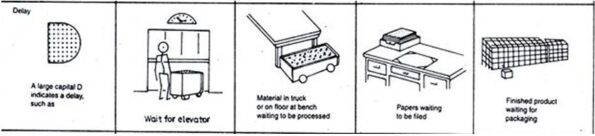

4. Delay

- Delay occurs when an object or operator is waiting for the next activity.

- Example: An operator waiting to get a tool in the stores. Work pieces stocked near the machine before the next operation.

5. Permanent Storage

- Storage takes place when an object is stored and protected against unauthorized removal.

- Example: Raw material in the store room.

Procedure:

- Study the operation cycle a few times before starting to record

- Provide all information about the job in the chart.

- Chart one hand at a time

- Start with the hand that handles the part first or the hand that does the most work. The exact point of starting is not really important, as the complete cycle will eventually come round to it again, but the point chosen must be definite.

- Add in the second column the kinds of work done by the other hand.

- Record actions on the same level which occur at the same moment.

- Care should be taken that no activity is left while recording, as it will affect the method study badly.

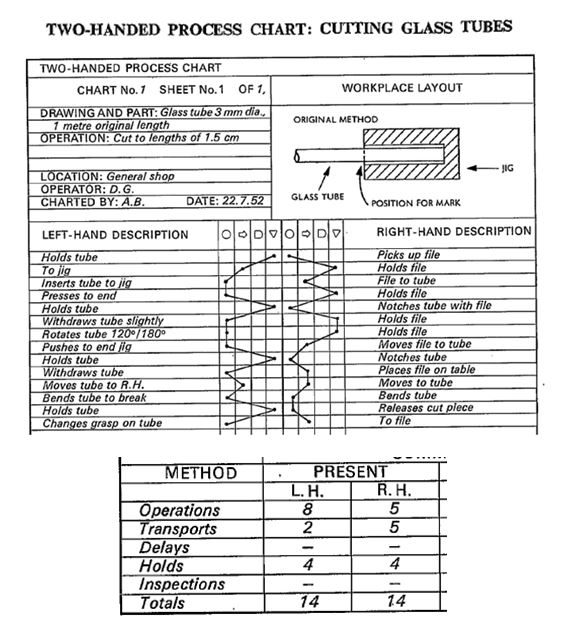

Example:

This very simple example is one taken from the work done by a trainee of the first I.L.O. productivity mission to India. The nature of the job (cutting off short lengths of glass tube with the aid of a jig) is explained on the form; the operations involved are self-explanatory.

An Article By:

National Institute of Fashion Technology