WHAT IS A GARMENT SPEC SHEET?

A garment specification sheet or spec sheet is a technical document that contains the construction details of the product, a technical diagram/ sketch of the garment and the measurements of a product.

Specification sheets are the blueprint of a product, sometimes referred to as the technical pack or tech pack, and should be as comprehensive as possible. 1

Garments specification sheet is an important document for manufacturing any garments. The main objects of providing garments spec sheet to the manufacturer is to facilitate the whole processes of garments manufacturing.

It is provided by the buyer to the garment merchandisers at the beginning of a garment export order and are normally receive garments specification sheet in soft copy (PDF file) from the buyer.2

DIFFERENCE BETWEEN A SPEC SHEET AND TECH PACK3

| BASIS | SPEC SHEET | TECH PACK |

| CATEGORIZATION | A spec sheet is just a part of complete fashion tech pack. | Contains spec sheet. |

| INFORMATION CONTAINED | Contains details of a particular style that a clothing manufacturer needs to prepare pattern for and measurement gradation between sizes and give the detailed size gradation. | Specify fabric details, washing and wash care, prints, etc other than the spec sheet details that go into apparel style detailing. |

NEED OF A PRODUCT SPECIFICATION SHEET

It is impossible to work/manufacture garments without any form of specification, and a written description or a verbal agreement is just not enough. Relying on sending only your sample to a factory 10,000 miles away is also not a good idea.

Before a product is finalized, it can be amended many times, and specification is the only accurate method to note any change.4

WHAT DO YOU NEED TO CREATE A SPEC SHEET?5

- Designers can use Adobe Illustrator to create a technical drawing or work with a technical designer.

- Writing specifications requires a thorough understanding of product in terms of cost and quality, the company and target market. Eg -If it is specified that all shoulder seams have to be taped, then additional cost must be computed for materials (the tape), labour, and the attachments for machines.

- Someone with pattern making or pattern knowledge must be involved with measurements & grading specification.

- Photographs and technical drawings should be included in the tech pack. Templates can also be found online that can help organize all the information.

- Separate worksheets in Excel contain details pertaining to the style such as grading, fabric & trims, fit comments. This should all be on available in one document.

- There should also be tech packs for all labels or details for packaging which may be added to a separate tab in the excel sheet.

- Most companies make use of database that includes information about the products, sample products of competitors, and the cumulative experience and the knowledge if their staff for the making of a specification sheet.

APPROVAL PROCEDURE

- When received initial samples from the supplier for evaluation, it is ensured that the buyer has seen and approved each garment first. This will include trying the garments on a figure to ensure that they fit correct and amendments to the size chart and specification might be necessary at this stage.

- It is buyer’s choice of factory, style, and fabric; they have agreed to a price and delivery date; and at the end of the day, they’re responsible if the items don’t sell.

- Buyers will expect to be kept up to date on the progress of their merchandise and want to know immediately of any problems find or changes might consider necessary. In some instances, an e-mail informing them is sufficient, but it needs to make an important change, go and talk to them first, explain the problem and why think it necessary to change the specification sheet, because at this point, it’s sods or Murphy’s law that the supplier will try and increase prices or delay the delivery.

- The amount of information that can include is almost limitless. However, need a minimum of information, and the priority is to highlight the most important features and characteristics of the product.

- Should try to include as much detail as possible within the time limit available and this does depend on how quickly and accurately can draw, and the process will be speeded up if already have a similar product in library of specification sheets. This demonstrates the advantages of using CAD.6

ELEMENTS OF SPEC SHEET

| Element 1

Describe the garment in detail. |

Performance criteria

Overall style is described in detail using accepted workplace terminology in terms of construction and finish. All features of the style are described in detail using accepted workplace terminology. (May include but is not limited to – breasted, type of lapel, buttoning, pockets, vents, panels, sleeve type, cuffs, yokes, collars.)The fabrics used are described in enough detail to facilitate ordering. Information recorded on the workplace specification sheet is in enough detail to allow the patternmaker to produce a draft pattern. |

| Element 2

Describe the embellishments incorporated into the design. |

Performance criteria

The embellishments incorporated into the garment are described in enough detail to facilitate ordering. (May include but is not limited to – types of buttons, stitching details, zips, domes, d-rings, toggles, prints, embroidery.) The location of embellishments is described in enough detail to allow their correct placement on the garment. |

| Element 3

Describe the interior of the garment. |

Performance criteria

Interior of garment is described in detail, in terms of construction, fabrics and finish.7 (May include but is not limited to – linings, labels, stitching detail, tabs, interior pockets.) |

| Element 4

Record information on a garment specification sheet. |

Performance criteria

(may include but is not limited to – garment sketches, written descriptions, embellishments, size range, colour range, fabrics, linings and interlinings, special stitching, style identification number, garment make instructions, label information.)8 |

SOURCES OF INFORMATION IN A SPEC SHEET

- Textbooks and reference books related to textiles design, product development, flat pattern, and manufacturing include a great quantity of information. Eg. Some introductory textiles book includes information related to yarn size, yarn twist, and fabric weight for many basic fabrics. This information can be referred to gain the elementary knowledge about the components of the garment.

- Standard test methods also help in writing specifications related to the characteristics, quality and performance of the materials because these documents identify the information to be collected in performing the testing and the form and type of information to be reported when the testing has been completed.

- Excellent sources of information are the products and the materials from which they are made.

- Another excellent source of information comes from the experience of the individuals involved in the manufacturing of the garment. Experience often incorporates significant professional knowledge and the personal use of textile materials.9

VARIOUS SECTIONS AND IMPORTANT AREAS OF A SPEC SHEET

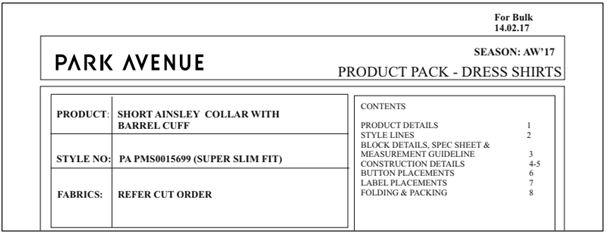

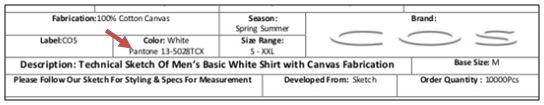

In spec sheet, each page should have a heading, to include a date, reference number, style, fabric, factory or customer and buyer, and page number. This will give a unique identity to each specification and each page of the specification.

This is especially useful when amending any part of the specification. The factory will be able to immediately locate the page that needs to be replaced. It could be considered safer to reissue the whole specification sheet with a note of what has been changed and ask the manufacturer to sign a form, acknowledging that it has received the amended specification and that it understands the changes.10

The following are present on every page of a specification sheet:

- Client Name, Brand Name, Email and Phone Number: a lot of enquiries are received everyday by manufacturers and suppliers. If correct contact details are not filled properly, contacting back to provide quotes becomes difficult.

- Date: This is the date in which the spec sheets are submitted. This allows the suppliers to track a proper timeline the project.

- Garment Description: What has to be made has to be indicated here that can be taken as a reference. This is a 1 to 3 word description such as skirt, 3/4 pants, short sleeved t-shirt, etc. It can be in the form of a style number such as “FALL16 – pants 001”.

- Number of Pieces: This would be the quantity of pieces for this specific garment style that needs to be produced.11

- Fabric details include Swatches, Product code, Fiber content and supplier details. Fabric indicates the type of fabric(s) that will be used for the garment.

It also includes the composition (if it is a blended fabric). The information has to be added for both the shell as well as lining fabric contents.

Each of the following information is present on a different page:

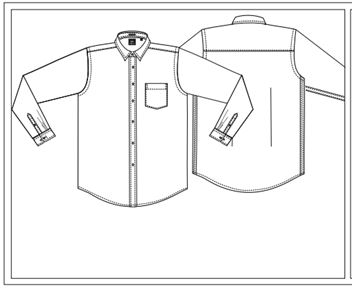

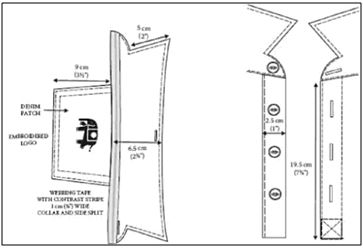

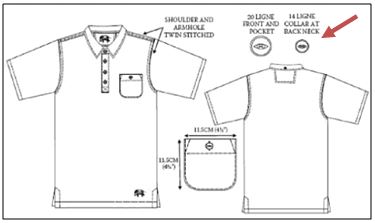

- Garment Front & Back Images/Sketches/Flat drawing: This is an image of the garment as seen in a straight front and straight back view. These can be drawings or photos. Drawings can be by hand or computer.12

A Flat Drawing is a technical drawing of a garment that is done in a very specific way. The line weights mean different things and there are a lot of rules around how they have to be laid out and what you can and can’t do. There is no styling, or illustration effects. They are simple, without fabric fills or textures. They have very little writing or text and purely focus on the technical information, like stitching and seams along with clear and accurate measurements.

Garment Front & Back

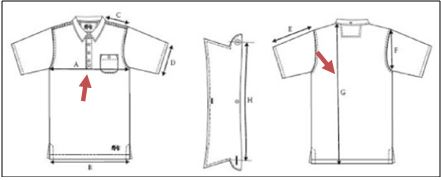

- Seam Indicator Lines: The manufacturers need to clearly see all the seam-to-seam measurements to understand fabric consumption, garment cut and style, and sizes. All measurements should be typed in centimeters. Image should be used as a guide to ensure having measurements, indicators, and correlating letters to highlight each seam.13

Seam indicator lines and measurements in cm

- Alterations: If there are any alterations required after the sample is completed, the buyers would indicate it here. For the initial sample, this would be left blank.

- Pantone Code: Pantone is the globally recognized company and authority on colour and colour coding systems.

Pantone code indication

- Screenshot of Colour/Print: Depending on the preferences and fabric choices, manufacturers choose to work with some of the pre-dyed fabrics available. Add an image of the colour in this space. If you wish to have a specific design printed onto your choice of fabric, then once again you’ll need to add a screenshot of it into the space provided in your spec sheets. Manufacturers need suppliers to send use the graphic designed image files before the printing can begin but for right now, an image will suffice and allow us to determine what method of printing will be best for your specific needs.14

Screenshot of required print

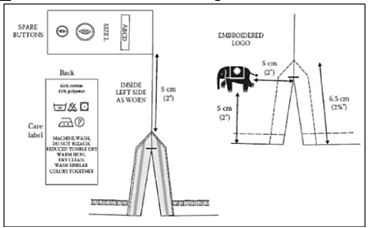

- Additional: If there are special trims or materials, specific stitching or any other supporting images that will help in your garment production, buyers add these into new cells or make additional notes. This could include such things as buttons, zippers, piping, snaps, clasps, etc. Addition of an image would make it easier for the manufacturers.

Buttons specifications

- PoMs (Points of Measure): The various size measurements of the required item. The PoM will be used to check that the measurements are correct on the finished garment.

Measuring points

- Print instructions: Information regarding the type of print on the garment and its placement. 15

Print instructions

- Embroidery Instructions: Information regarding the type of embroidery, its size and placement.

- Folding and packing instructions: Complete instructions and steps of folding the garment along with the packing instructions (including the dimensions, materials and sources of packaging material) are provided.

Packaging instructions

- Stitch instructions: Details of stitch type, thread to be used, and stitch length.16

Stitch instructions

- Garment washing instructions: Details of wash finishes for items such as denim garments.

Washing instructions for jeans

- Accessories instructions: Trim details, fastenings required with product codes, fiber content and supplier details.

- Label instructions: Placement details for brand logo labels and care labels.

Label and embroidery details

- Comments section: Used by the factory to make a note of anything related to the construction of the garment. 17

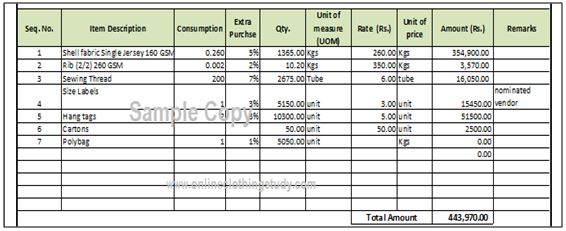

- BOM(Bill of materials): BOM(Bill of materials): A bill of materials (also known as a BOM or bill of material) is a comprehensive list of parts, items, assemblies and other materials required to create a product, as well as instructions required for gathering and using the required materials. The bill of materials can be understood as the recipe and shopping list for creating a final product. The bill of materials explains what, how, and where to buy required materials, and includes instructions for how to assemble the product from the various parts ordered. All manufacturers building products, regardless of their industry, get started by creating a bill of materials (BOM).18

Bill of material

The Points of Measure (PoM) are very important to ensure accurate execution of the garment during its production. Below are some basic PoMs that should be included on the Garment Spec Sheet, for different garments:

MEASUREMENTS REQUIRED FOR:

TOPS

- HPS (High Point Shoulder): Located at the highest point of the shoulder, where the shoulder seam meets the neckline.

- CF (Centre Front): An invisible line that runs vertically down the centre of the front of the garment.

- CB (Centre Back): An invisible line that runs vertically down the centre of the back of the garment.

- SS (Side Seam): The seams on the right and left sides of the garment from the hem to the base of the armhole.

TOPS/JACKETS/DRESSES

- Body Length: The garment length from HPS to the bottom of the hem, measured through the centre.

- Across Chest: This measurement is taken 2.5cm below the armhole, horizontally from edge to edge.

- Waist: This measurement is usually taken horizontally from edge to edge and at a distance of 39cm below the HPS.

- Hip: This measurement is usually taken horizontally from edge to edge and at a distance of 61cm below the HPS.

- Garment Base Width: The measurement of the bottom edge of the garment is taken horizontally straight across from edge to edge.

- Sleeve Length: The distance from the top of the sleeve to the hem of the sleeve.

- Bicep: Measured 2.5cm below the armhole, perpendicular to the length of the sleeve.

- Armhole Curved: This measurement is taken along the curve of the armhole seam where the bottom armhole meets the side seam, to where the top of the armhole meets the shoulder seam.

- Shoulder Drop: The measurement from the HPS to the shoulder seam at the armhole.

- Neck Opening: The measurement from neck seam to neck seam at HPS.

TROUSERS

- Upper Waist: Measured by aligning the front and back waistbands and measuring straight across the top of the waistband from edge to edge.

- Lower Hip: This is obtained through the 3 point method using three points of measure marked at a certain distance below the top waist at the sides and CF. 19

- Thigh: This measurement is taken 2.5cm below the crotch seam, perpendicular to the trouser leg from side to side.

- Knee Opening: This measurement is taken 30.5cm below the crotch, and perpendicular to the trouser leg from side to side.

- Leg Opening: This measurement is taken horizontally across the bottom edge of the leg opening.

- Front Rise: This measurement is taken at the centre front seam, from the crotch seam to the top of the front waistband.

- Back Rise: This measurement is taken at the centre back seam, from the crotch to the top of the back waistband.

- Inseam: This measurement is taken at the inner leg seam, from the crotch seam to the leg opening.

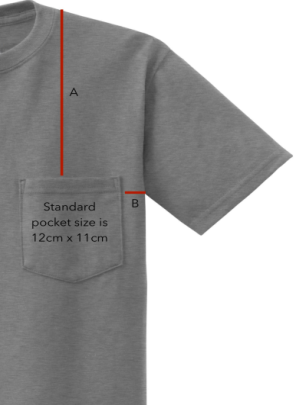

T-SHIRT (Navy, short sleeved)

T-SHIRT (Navy, short sleeved)

The correct way to provide to take measurements is to draw a line for a specific seam or opening, then indicate which measurement it is with a letter.

Here is how measurements for a t-shirt are provided:

(A) sleeve opening; (B) sleeve length (top); (C) shoulder length; (D) neck width; (E) neck depth; (F) body length; (G) armpit; (H) sleeve length (bottom); (I) chest width; (J) waist width; (K) hip width.

* If you choose to do a v-neck, we will need to know the length of the V (A and B).

** If you choose to add a pocket, we need to know (A) how far down from the shoulder it is and (B) how far in from the side seem it is.

*** If you are doing a long sleeve t-shirt, we will need to know the (C) neck trim and (K) cuff trim.

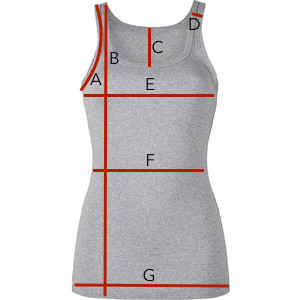

SINGLETS & TANK TOPS

SINGLETS & TANK TOPS

While producing singlets or tank tops, including (A) Shoulder opening; (D) shoulder strap width must be ensured. This example is for a woman’s tank top but the same measurements will apply for men’s too. 21

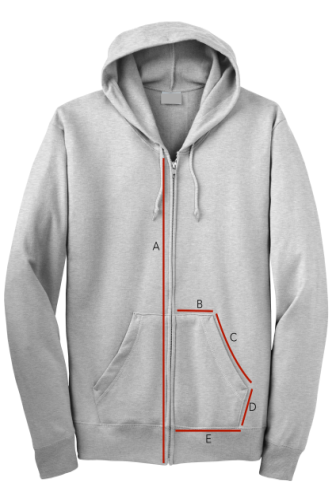

HOODIES & JUMPERS

HOODIES & JUMPERS

When outlining measurements for these tops, the same measurements apply as on the long sleeved t-shirts. In addition, we will need to know (B) hood circumference. If the design has a single pocket or if your design is a zip-up hoodie, we will need to know (A) length of zipper

(B) Pocket width (top)

(C) Pocket opening length

(D) Pocket depth

(E) Pocket width (bottom).

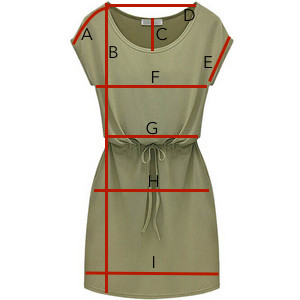

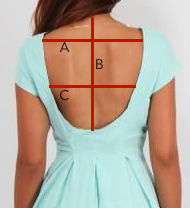

BASIC DRESSES

When measuring for a basic dress, the measurements for

(A) sleeve length;(B) full front length; (C) neck depth;(D) neck width; (E) sleeve opening; (F) chest width; (G) waist width; (H) hip width;(I) bottom width need to be considered.

Additionally, if there are special details in the back of the dress, their measurements are also to be known. Depending on the style, a variety of measurements may be required as shown above. 22

SHORTS & TROUSERS

While shorts or trousers, the details and measurements of (C) band height; (D) crotch height; (E) pocket opening – if this applies; (F) inseam; (G) cuff height – if this applies; (H) leg opening are required. Any details that they may be on the back of the shorts or pants such as pockets or buttons and the distance these elements are from any specific edge or seam are also to be included.

The measurements for board shorts are similar to regular shorts along with

(A) Shorts length

(B) Waist

(C) Crotch

(D) Band height

(E) In seam

(F) Leg opening. Pockets on the front or the back (if any) are also to be added. For bikinis, all of the measurements shown in the example images below are to be provided.23

PROCESS OF DEVELOPING A SPEC SHEET

STEPS IN IMPLEMENTATION

A specification sheet package may include complex technical sketches, pattern and/or garment measurements, methods of measurements charts, embroidery/screen and label placements. A specification sheet will be developed based on the design of the products and the requirements of the clients or producer itself on the quality, standards, key or all materials and so on.

- At the top of the specification sheets is the information about the products such as company name and logo, product name and description, style code, and a sample design/picture of the product design.

- The specification sheet must have specific information about the product including key dimensions such as length, neck round, waist, shoulder as well as other dimensions of the products in different standard sizes such as small, medium, large, or extra large.

- Information on types and quantity of some important details such as buttons or types of fabric.

- Samples of sub-materials/fabrics and accessories such as buttons and zips should be added to the specification sheet for better reference.

- A specification sheet can also include guidelines and key production steps such as cutting, sewing, or ironing the garments. It may also include guidelines for important details such as buttons, edges, or threads.

- It may also include guidelines on what measures to take in case of mistakes or errors.8. Specification sheets should be posted on a bulletin board so that all workers who might need them can access the most up-to-date information. This bulletin board should be placed in a public place that is easily accessible by all workers, such as at the beginning of the production line. 24

- Copies of specification sheets can also be put into a clear box or plastic folders attached to the bulletin board so that workers can see them and take copies out easily.

- Another copy of the specification sheets should be posted at the quality control station in well lit conditions so that the QC staff can easily check each product against the specifications.

- Make sure that all the workers and QC staff understand the specification sheets in the same way by conducting a short interval training or instruction session on understanding and using the specification sheets.

- Store all specification sheets in excel spreadsheet or word format so that they can be easily tracked and shared. This is also a good format for communicating the information in the specification sheets with the technical team prior to production.

SOURCES REQUIRED TO DEVELOP A SPEC SHEET

- Technical staff involvement to create the specification sheets.

- Bulletin boards, paper, and boxes and folders at the bulletin boards.

CHALLENGES AND PITFALLS

- Difficulties to make workers with limited knowledge understand the specification sheets in a consistent way.

- Diagrams, illustrations, photographs, samples, definitions and examples are used to clarify the specifications. But, care must be taken to assure that these aids do not confuse the interpretation.

INDICATORS FOR MONITORING

- Specification sheets developed and made available at the beginning of production lines and at quality control stations.

- Workers and quality control staff understand the specification sheets in a consistent way.

EXAMPLES OF A SPEC SHEET

An important aspect of quality assurance is to match products with suitable factories. New factories trying to build up their customer base will sometimes offer to make products that they are not used to making; they are only focused to getting orders, but in long run, this can waste a lot of time and create many problems. 26

However, detailed your specification is, it’s the interpretation of the detail that is most important and that can only be done by factories that are constantly making that kind of product. For example, a factory making unstructured jackets will struggle with tailored jackets because it is unlikely to have the right skills or machinery.

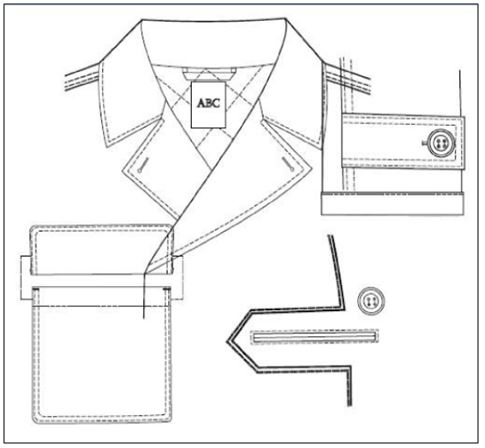

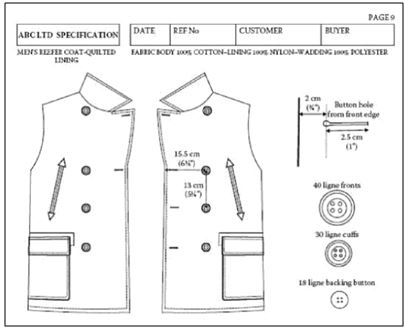

REEFER COAT

This specification could be based on a similar style garment and the existing specification quickly modified to a new style.

For this coat, the buyer has specified cotton for the outer, but the weight and the construction are to be finalized, and the buyer might decide on a blend of cotton and polyester. Rather than trying to put all the details on one page, it is better to create pages for each section of the garment.

Reefer Coat

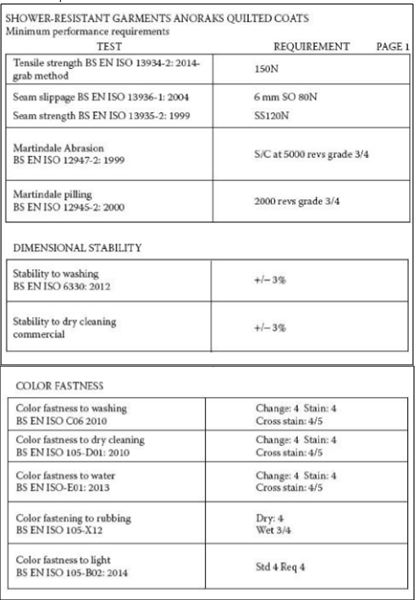

- The first page of the spec sheet, as shown in the pictures below, is the minimum textile performance required.26

Shower resistant garments, anoraks and quilted coats: minimum textile performance required

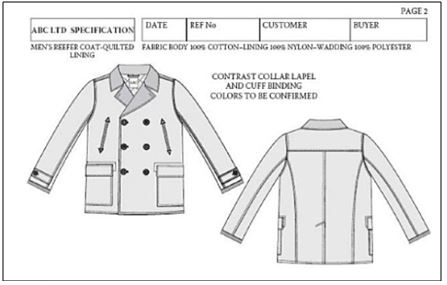

- The page shown in the image below is the overall look of the garment.

The overall look of the garment

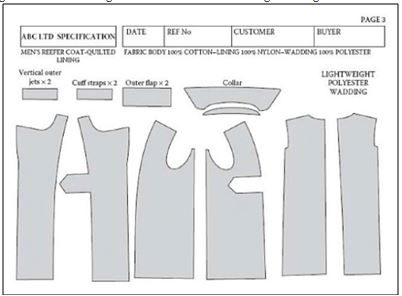

- The page shown in the image below shows the interlinings of the garment.26

The interlinings of the garment

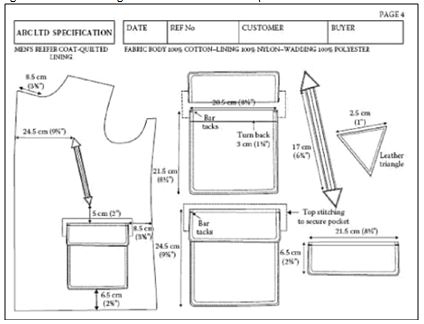

- The page shown in the image below is the front with pocket details.

Front with pocket details

- The page shown in the image below is the back and cuff details.26

Back and cuff details

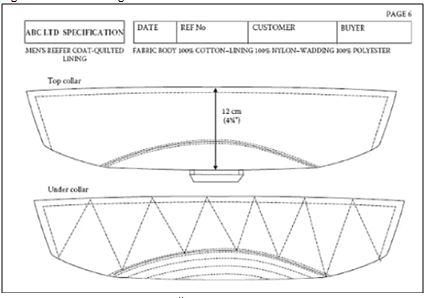

- The page shown in the image below shows the collar construction.

Collar construction

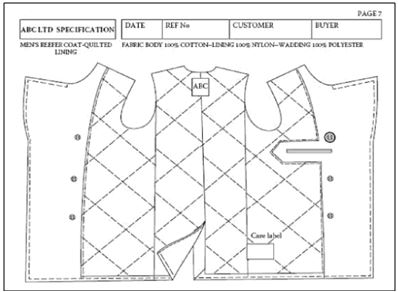

- The page shown in the image below shows the design and construction of the inside lining of the garment.26

Design and construction of the inside lining

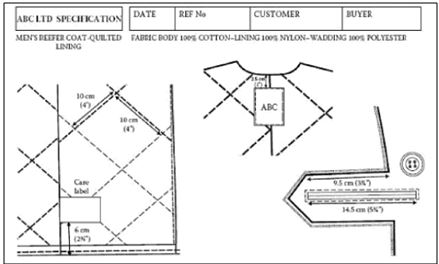

- The page shown in the image shows the individual components of the garment.

Individual components of the garment

- The page shown in the image shows the buttons and buttonholes.26

Details of buttons and buttonholes

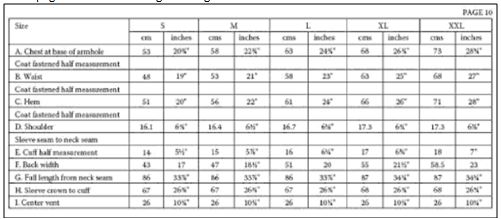

- The page shown in the image is the garment size chart.

Garment size chart

- The page shown in the image shows the size chart, measuring points.26

Size chart, measuring points

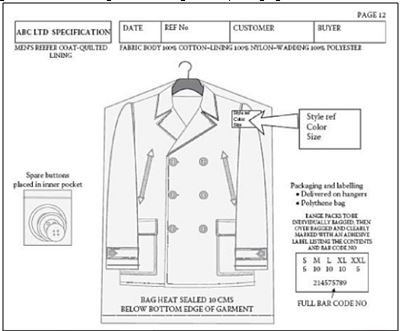

- The page shown in the image shows the garment packaging.26

Garment packaging

An Article by

Ritika Pathania with Anushka Girdhar

REFERENCES

- The Fundamentals of Quality Assurance in the Textile Industry by Stanley Bernard Brahams

- http://www.garmentsmerchandising.com/9-key-points-of-garment-specification-sheet/

- https://www.paromitadas.com/clothing-designer/specification-sheet-and-tech-pack/

- The Fundamentals of Quality Assurance in the Textile Industry By Stanley Bernard Brahams

- Managing quality in apparel industry-PV Mehta and S K Bhardwaj

- https://www.scribd.com/document/220028115/Specification-Sheets-in-Garment-Industry

- www.nzqa.govt.nz/nqfdocs/units/doc/25241.doc

- www.nzqa.govt.nz/nqfdocs/units/doc/25241.doc

- Quality assurance for textiles and apparel-Sara.J.Kadolph (page-63)

- The Fundamentals of Quality Assurance in the Textile Industry By Stanley Bernard Brahams

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- http://www.createafashionbrand.com/tech-pack-vs-spec-sheet-whats-difference/

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- https://insider.utelier.com/toolkit/business-basics/what-is-fashion-spec-sheet/

- https://insider.utelier.com/toolkit/business-basics/what-is-fashion-spec-sheet/

- https://www.arenasolutions.com/resources/articles/creating-bill-of-materials/

- https://insider.utelier.com/toolkit/business-basics/what-is-fashion-spec-sheet/

- https://insider.utelier.com/toolkit/business-basics/what-is-fashion-spec-sheet/

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- https://www.clothingmanufacturingagentbali.com/how-to-fill-in-spec-sheets/

- https://www.scribd.com/document/220028115/Specification-Sheets-in-Garment-Industry

- https://www.scribd.com/document/220028115/Specification-Sheets-in-Garment-Industry

- The Fundamentals of Quality Assurance in the Textile Industry By Stanley Bernard Brahams