Given below are are different types of testing equipment used in apparel sector to maintain the quality level of end product. The list is not exhaustive and will be updated.

- Pilling Tester

Purpose: To test the pilling (hair ball) characteristic of fabric

Process: A fabric specimen of 10cm X 12cm is rolled around a rubber tube and turned in a winding box for a period of time

Result: The specimen is compared to normal fabric

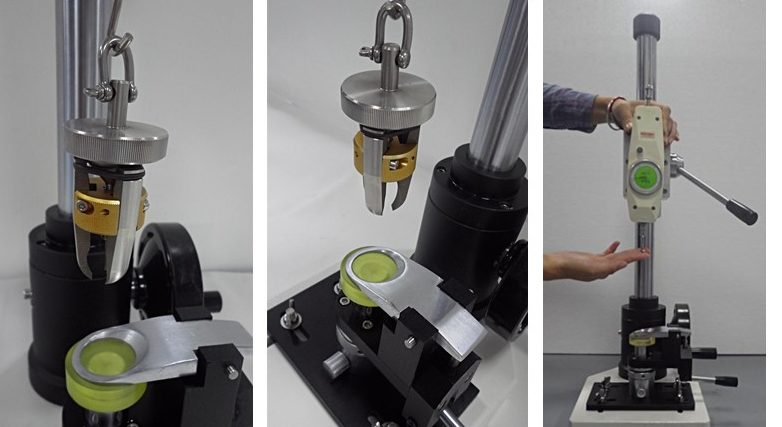

- Button Pull Out Tester

Purpose: To test the strength of a button by determining the force it will take until it breaks. Suitable to grip buttons from 5mm to 25mm.

Process: A test specimen with a button is placed on the fabric clamp. The button is pulled out with the help of a top flywheel puller with a force of 19N for 10 seconds.

Result: If the button does not break at 19N force for 10 seconds, it is approved

- Tear Strength Tester

Purpose: To determine the resistance of the fabric to tearing

Process: A fabric specimen of 63mm x 76mm is made on which a slit is made with about 1.7 inches (43mm) remaining to be torn after the initial tear. The pendulum with a base weight of 3200g is released to propagate the slit through the remaining 43mm.

Result: (3200 x reading)/100 = Tear Strength (in grams)

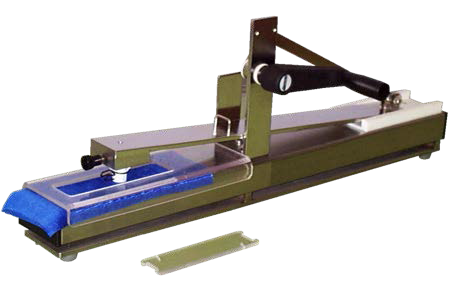

- Crockmeter

Purpose: To determine the amount of colour transferred from fabric on other surfaces by rubbing (both dry & wet conditions)

Process: A fabric specimen of 19 x 25.4 mm is positioned on the base of the Crockmeter on which rubbing action is provided by a 16mm diameter acrylic “finger” with a constant load of 9N. This rubbing action is continued for 10 cycles, each of 1 second. A standard crocking cloth made of 100% combed cotton is used as an abradant.

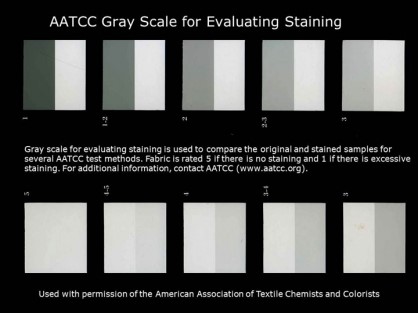

Result: The amount of colour transferred to the abradant is assigned a grade using the AATCC Grey Scale in the Colour Matching Booth.

Colour Matching Booth:

A colour matching cabinet which accurately measures the colours of the material under standard light sources to reduce down the interference of external lights and effect of light on the colour quality of the material.

The Colour Matching Booth consists of four standardized lights:

- D65 (Daylight)

A light bluish coloured light source which accentuates blue and subdues green and red. It is the specified daylight source for ASTM D1729-2016.

- UVB (Ultraviolet B)

UV energy has the ability to excite optical brightener agents (OBAs) and fluorescent dyes and pigments within a sample causing them to emit light in the visible spectrum, usually in the blue region

- Cool White Fluorescent (CWF)

It is characterized by emitting high amounts of green and very little red energy. It has a color temperature of approximately 4150K and a CRI(Colour Rendering Index) of approximately 62.

- TL 84

A narrow band tri-phosphor fluorescent source characterized by emitting high amounts of green energy, with a color temperature of approximately 4100K. It has a CRI of approximately 86.

- Incandescent Light

GrayScale:

The arrangement of achromatic gray chips in a scale from light to dark. The rating is from 1-5, 1 rated as the least, i.e., maximum staining while 5 is the best.

- GSM Cutter

Purpose: To measure the weight of the fabric

Process: Place the fabric specimen on the GSM Cutter pad in such a way that no crinkle is formed. Cut the fabric using the gsm cutter and weigh this swatch using an electronic balance

Result: Multiply the reading of the electronic balance by 100 to get the reading in g/m2.

- Washing Machine

Purpose: To determine the response of fabrics to washing

Process: The fabric undergoes normal wash at a temperature of 30°C. There are 5 wash cycles, each of 30 minutes. Multi-fiber cloth is also washed with the fabric.

Result: The fabric is observed for physical changes of size, colour and appearance and staining on multi-fiber cloth is observed

- Laundrometer

Purpose: To evaluate colorfastness and staining potential of fabrics under accelerated wash condition

Process: Take a fabric specimen of 10”x4” along with a multi-fiber cloth and load it in the laundrometer. The laundrometer consists of 10 steel balls, which rotate with the fabric. The common detergent used is ECE Phosphate Reference Detergent ‘B’ (4gpL) and sodium (1gpL) with the sodium per liquor ratio as 1:150. The cycle duration is 30 minutes at a temperature of 40°C.

- pH Meter

Purpose: To test the pH of the garment

Process: A fabric swatch of 2g weight is cut and is dipped in 100mL KCl solution (0.1M/litre). This solution is agitated using a rotary flask shaker for 2 hours at 30 rpm.

- Perspirometer & Test for Saliva

Purpose: To determine the colour fastness of textiles to perspiration

Process: The fabric specimen of size 100mmx40mm is immersed in both acidic and alkaline solutions. The specimens are then placed on the acrylic plates along with the multi-fiber under a weight of 5kg. This is placed in the incubator for 4 hours at 37°C.

Result: The degree of staining is evaluated using a Grayscale