There are several different ways by which coloring materials are classified; the following are the most useful ones for the dyer:

1. Classification according to solubility

2. Soluble dyes (anionic or cationic)

3. Disperse dyes (non-ionic, very slightly water soluble)

4. Pigments (insoluble)

2. Classification according to method of application

- Acid dyes (protein fibers, polyamides, etc.)

- Basic dyes (acrylics, basic dyeable polyester, etc.)

- Direct dyes (cellulosic, and some others)

- Azoic dyes (cellulosic)

- Vat dyes (cellulosic)

- Reactive dyes (cellulosic, and some others)

- Disperse dyes (polyester, acetates, polyamides, acrylics, and other hydrophobic fibers)

3. Classification according to chemical constitution

- Azo dyes and pigments (mono \Azo, diazo, etc.)

- Carbonyl dyes and pigments (anthraquinone and indigo derivatives)

- Cyanine dyes

- DI and triphenylmethane dyes

- Phthalocyanine dyes and pigments

Currently dyes and pigments are used to impart color to the textile materials. In order to perform the coloring materials should have the following features.

| PIGMENTS | DYES | |

| 1 | Intense color | Intense color |

| 2 | Insoluble in water & Common solvents | Must have solubility in water during dyeing stage |

| 3 | Are not made to have substantively to fibers | Must have substantively to the fiber during dyeing stage. |

| 4 | Molecular size varies from small to large size | Molecular size must be small enough to allow the molecules to penetrate the fibers. |

| 5 | Stable to further treatments in

Production &normal use |

Stable to further treatment in production and normal use. |

| 6 | Durability depends upon binders used | Able to acquire durability to wet treatments. |

The selection of dyes depends on

- Suitability of dye to various uses of fabric;

- Fiber Content and fabric structure;

- Required color fastness;

- Penetration and absorption of dyes;

- Cost of dyestuff;

- Methods of application

s.

THE DESCRIPTION OF COLOUR

One of the earliest and commonly used today is the Munsell System. In the Munsell system a huge collection of painted samples is arranged by describing every colour by describing every colour by its three attributes: Hue, Value, and Chroma.

Hue is the attribute of colour by means of which it is described as being yellow, blue, red, etc. The following colours are used in the Munsell system: violet, violet-blue, blue, blue-green, green, green-yellow, yellow, yellow-red, red, and red-violet. Each of these hues is further divided into ten subdivisions.

Value expresses the lightness or darkness of the colour. This is the characteristic that describes the colour as lighter (brighter) or darker (duller). Value is expressed by a number 2 to 9 on a scale of 1 to 10 where 1 is and ideal black and 10 is an ideal white. Thus, when tow colours have the same hue but differ in their value number, the one with a higher value number is brighter.

Chroma is the strength or purity of the colour. This is the characteristic that indicates the saturation of the colour or the amount of colour (hue) in the object compared to a gray colour with the same value. Accordingly black, gray, and white have zero chroma. Chroma is expressed by numbers of 1 to 12, where a higher number corresponds to a colour with a higher saturation.

IMPORTANT PROCESS PARAMETERS OF DYEING

Dye bath

For the reproducibility, all the amount of dyes and dyeing assistants and the liquor ratio used should be measured and recorded accurately, in order to be followed precisely in future runs. All dyeing assistants in any dye bath should be used only if necessary. Using excessive amounts (larger than recommended) of any additive should be avoided.

The rule of thumb is that any dyeing assistants should not be used unless necessary .For example, certain retarders in dye bath is used to slow down the rate of exhaustion .If however. Heating the dye bath at a slower rate is sufficient to control exhaustion then it might be better not to use a retarder at all.

The concentrated Dye solution

To insure uniformity throughout the dyeing bath, a small solution or dispersion of the dye (s) is made first. Extreme care must be practiced in the preparation of these concentrated solutions or dispersions. Undissolved or undispersed dye particles, may cause un-level dyeing or form specks on the goods. Therefore, the dye solution is filtered through a coarse filter before entering the system. Also, when preparing concentrated solutions, dyes and dyeing assistants should not be mixed together in their concentrated form unless specifically required.

To ease the handling and dissolving ( or dispersing ) of the dyes , the physical forms in which they are supplied have been greatly modified over the years .Today dyes are available in different forms . among them is a liquid form ready for use that needs only to be diluted to the desired concentration.

Material to liquor (M: L) ratio

This ratio indicates how much liquor is to be taken for dyeing a given weight of the material .The total quantity of water to be taken for dyeing depend upon the weight of the material to be dyed and is expressed in terms of M: L ratio . Thus a M : L ratio of 1: 20 means that the weight of the liquor to be taken should be 20 times the weight of the material to be dyed . If the weight off the material is, say, 1 kg then the weight of the liquor should be 20 times this is i.e. 20 kg or 20 liters. In hand dyeing. The M: L ratio is very high viz. 1: 20 or even 1:40 but in machine dyeing, this ratio is quiet low e.g. in jigger dyeing it is about 1:7 and in padding mangles it is about 1:1 .Lower M: L ratio is beneficial because the consumption of water, steam and chemicals with a high M: L ratio.

Percentage of shade

When the textile material is dyed with a particular dye or a mixture of dyes, then the amount of dye present on it after dyeing is expressed as a “per cent shade”. It is based on the weight of the material taken for dyeing. Thus when a 2% shade is to be produced on the cloth, then 2gm of dye is taken for every 100gm of cloth for dyeing .The dyeing so produced gives a 2% shade .It does not mean that the cloth contains 2gm of dye per 100gm of cloth after dyeing.

Depending on the per cent shade, dyeing have been arbitrarily divided into 3 groups viz. light (up to 0.5% shade), medium (from 0.5 to 1.5% shade) and dark (above 1.5% shade) .In the case of azoic dyes, the shade is expressed as light, medium, or dark .In the case of printed goods, the per cent shade has a different connotation .It is based on the weight of the printing paste and not on the weight of the textile material. Thus a 2% shade on the printed fabric means that the shade is obtained by using 2 gm of dye per 100 gm of printing paste.

Temperature control / rate of dyeing

When a substance is dyed under constant conditions dye absorption will increase until a dynamic equilibrium is reached .At equilibrium, no further change in concentration of dye, in fiber or dye bath, takes place. In general, increasing temperature of dyeing increases the rate of dyeing, but decreases the percent exhaustion at equilibrium. As temperature increases the fibers open up, allowing a faster absorption of dye. However, the increase in temperature will make it easier for the dye to move back into solution.

Wash cycles

This treatment removes un-bonded dyes and dyeing assistants from the fibers, and its procedure varies from a mild rinse with warm water to the use of a detergent solution at or near the boil. With certain groups of dyes, a slight change of shade occurs at this stage yielding the true color. Bleeding of dye from a new cloth in the first laundering could be the result of poor rinsing in this final stage of dyeing process. Further bleeding of the dye in subsequent launderings, however, indicates poor wash –fastness

Objectives of dyeing

- Color the Textile substrates [fibers, yarns, fabrics& garments] uniformly and producing uniform leveling.

- Achieve acceptable durability of color to further treatments in production and normal end use.

- Reproducing the required shade from batch to batch

- Using reasonably priced dyes and dyeing procedure

- Operating according to ecological requirements and carrying out in the shortest possible time

METHODS OF DYEING

Solution dyeing “Dope dyeing”

Method of coloring that is actually part of the manufacturing process of man mad fibers; the coloring agents are mixed to polymer solution of man made fiber before it is extruded through a spinneret.

Important features: –

Solutions dyed colors are fade proof under all conditions; Color fastness to light is out standing mainly used for Draperies, out door carpets, Automotive fabrics Other applications where long sun light exposure. To produce darker shades in blue, black, brown and green are widely used in fashion apparel fabrics because, range of colors is very limited. Very expensive

- Perfect color re production consistency from dye lot to lot can be achieved.

- Solution-dyed fabrics of acetate do not gas fade.

DYEING MACHINES / EQUIPMENT

Objectives of dyeing machines

To provide maximum contact between the dye liquor and the fibers within reasonable amount of time, without causing damage to the substrates.

STOCK DYEING

Circulating the dye liquor continuously dyes loose fibers through fibers.

Important features;

Expensive method of dyeing; Production is less10-15% waste of dyed fibers during yarn spinning; excellent penetration of dye in to fiber; Fashion risk final color of the fabric has to be desired earliest stage in its manufacture; Reason for use: Heather-like effect’ for woolen yarns or to produce “Mélange yarns”

YARN DYEING

Dyeing is carried out in yarn stage. Cheaper than stock dyeing; Excellent color penetrations of dye into fiber than piece dyeing;

Reason for use; To produce stripes, plaids and checks and other multi colored designs.

SKEIN DYEING

Immersing large loosely wound hanks (skeins) of yarn into dye vats; Suitable for knits and carpets where a fuller bulk is more desirable; Cotton, woolen, silk and bulk acrylic yarns are commonly used.

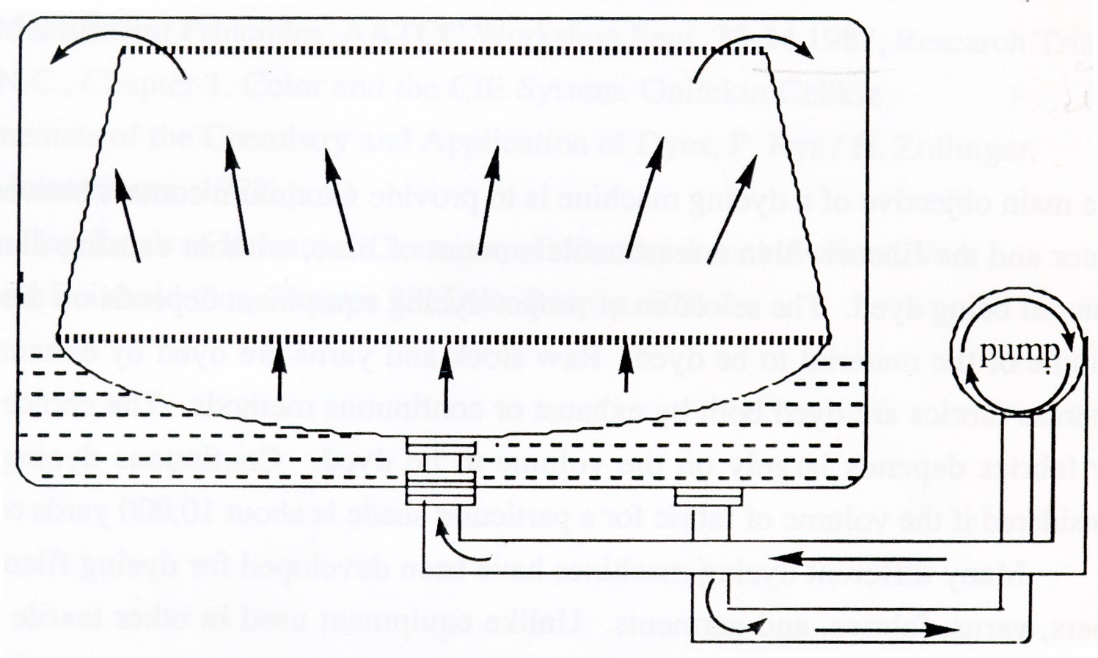

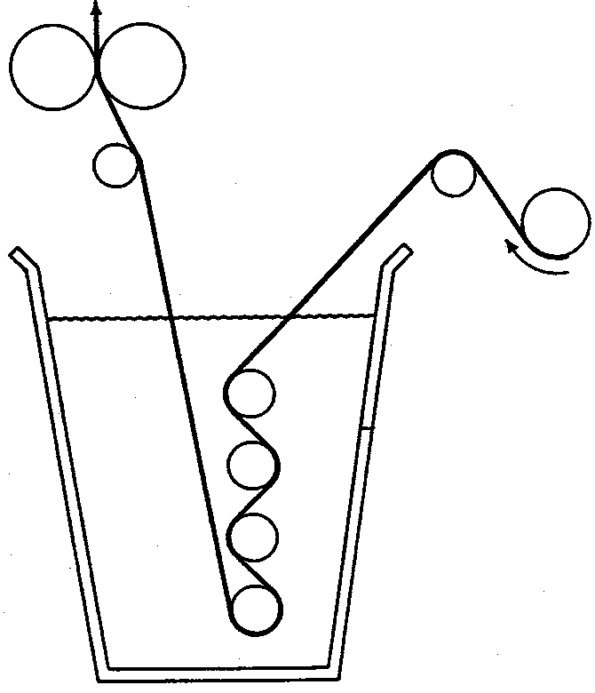

PACKAGE DYEING

More suitable for woven and knitted fabrics; Can be performed larger scale; Gives uniform results; Yarn package is stationary and dye liquor is circulated from inside to outside of the package; Package tension is critical factor to get uniform dyeing; Can be used for to due loose fibers, slivers, warp yarns and fabric with proper modification

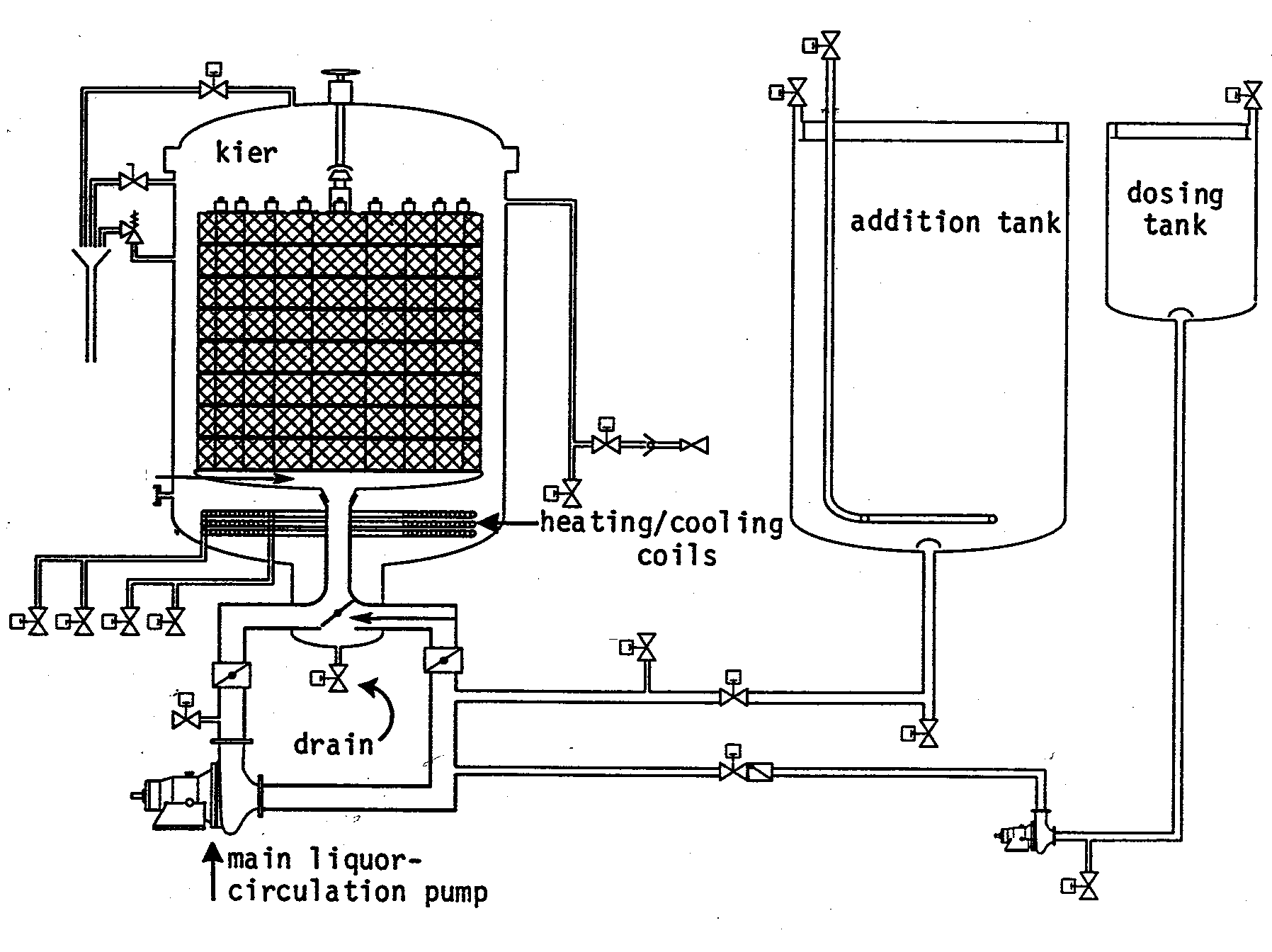

BEAM DYEING

Larger version of package dyeing; Yarns or full width of woven or knitted fabric is wound on to perforated cylindrical beams and enclosed in to a container. Dyestuff is circulated under pressure through perforation, same as package dyeing; Warp yarns are dyed a solid colour prior to weaving / warp knitting; Provides for good color absorption; Better color fastness than piece dyed methods.

PIECE DYEING

Dyeing is carried out in fabric stage, generally to produce single solid color in the substrate.

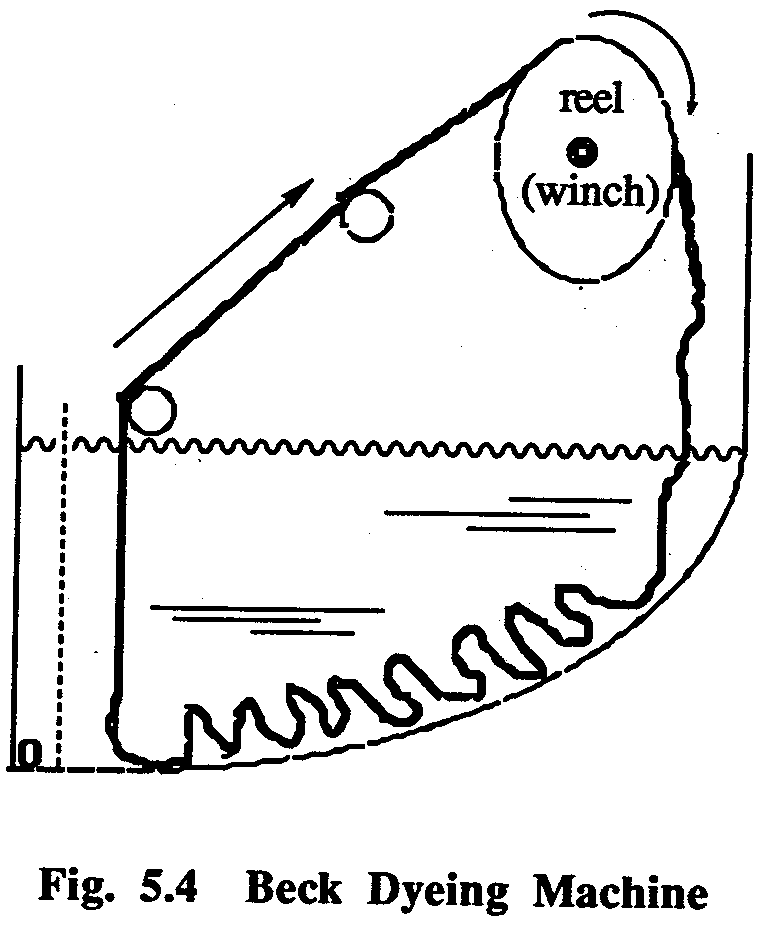

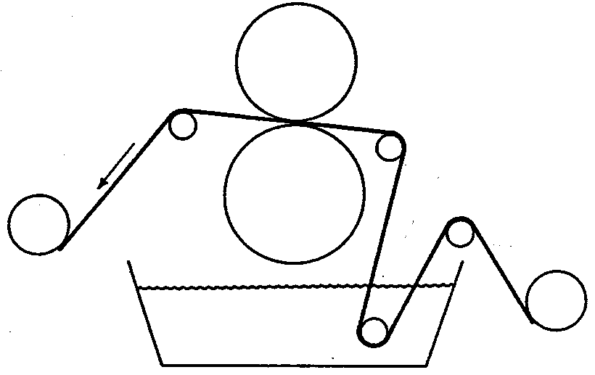

WINCH DYEING/BECK DYEING

Conventional dyeing machine; It consists a tub containing the dye liquor, and an elliptical winch or reel which is located horizontally above the dye bath. Fabric with ends stitched together to make continuous rope form is passed through the dye bath and submerged repeatedly. Fabric is held in a slack or loose condition during dyeing.

Mainly used for knits and lightweight fabrics; Filament yarn fabrics should not be dyed; Very light weight fabrics should also be avoided; Dyeing is carried out at high liquor ratios. (1:20 to 1:50); Low substantivity dyes (Reactive dyes) are not advisable; difficult to maintain uniform temp throughout the dye bath.

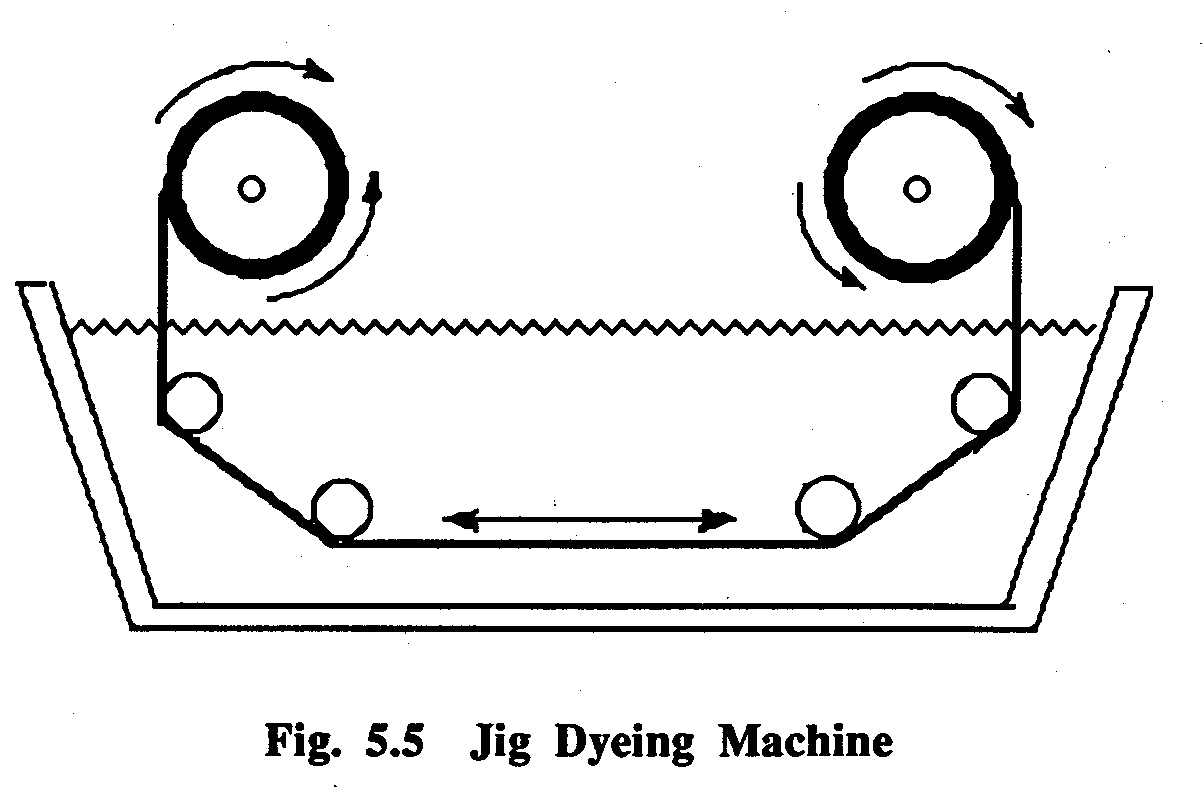

JIG DYEING MACHINE

Fabric is dyed in its open or full width. The machine consists of a small tub and two drawing rollers located above the dye bath. First the fabric is wound around one of the rollers; during dyeing the fabric is passed through the dye bath and rewind on to the second roller. When all the fabric is passed through the dye bath the direction of movement is reversed, this would be repeated until the dyeing is completed. During dyeing tension is imparted in length of the fabric:

Suitable for delicate fabrics & light wt. Fabric; Low liquors ratios (1:2 to 1:6) the consumption of chemicals and energy is low; In new jigs are equipped with devices that allow a reduction in tension applied in lengthwise; Knitted and stretch woven fabrics can not be used; Possibility of shade variation center to selvedge.

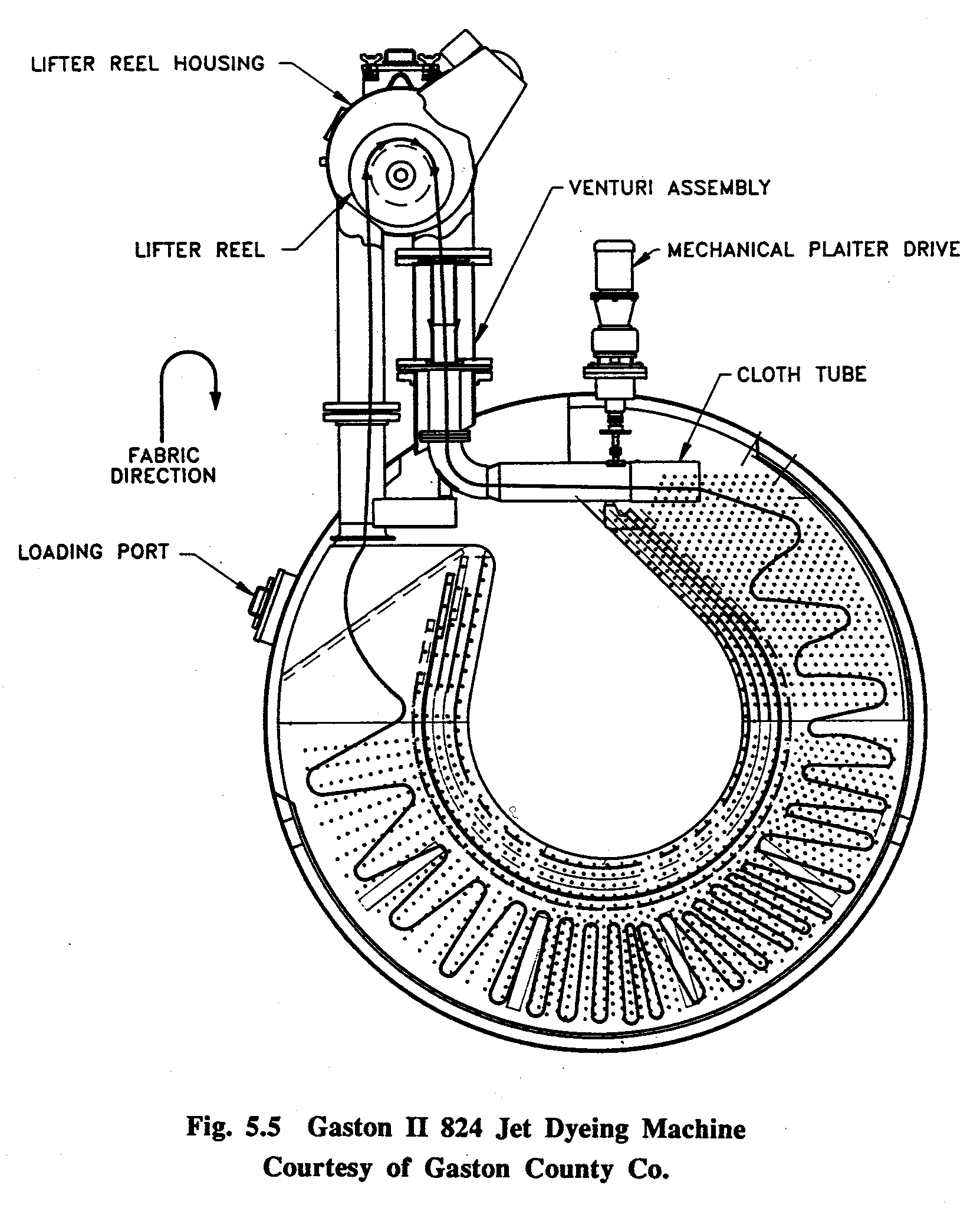

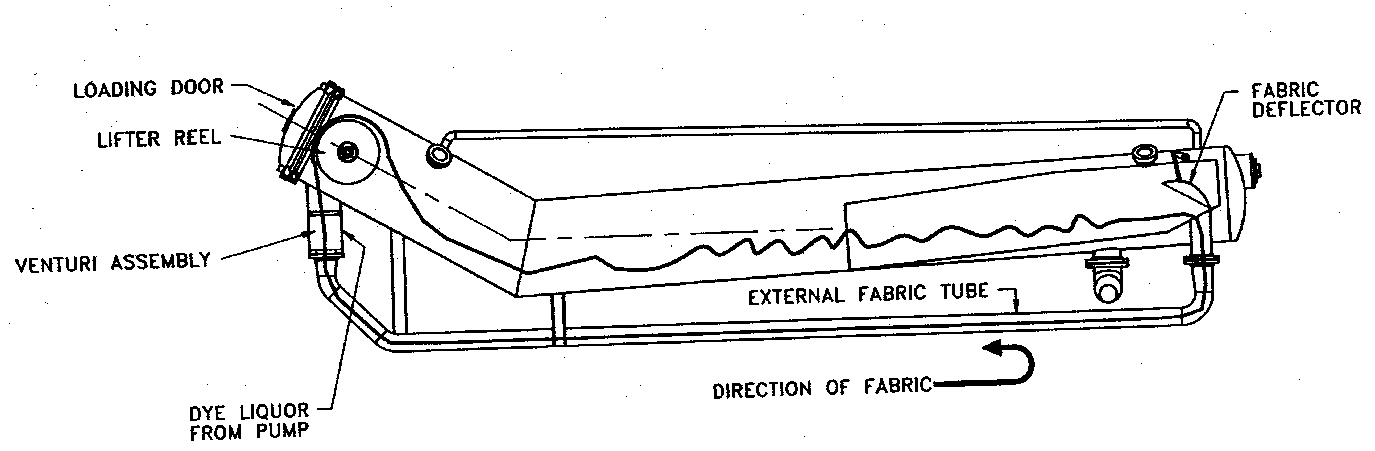

JET / SOFT FLOW DYEING MACHINE

Jet dyeing is a very efficient contact between the dye liquor and fabric is obtained by both are tin constant movement. This result improved level of dyeing shorter dyeing time. Fabric is circulated through the dye bath in rope form. The movement of the fabric occurs by circulating the dye-liquor through a venturi jet. Jet dyeing M/C’s are pressurized and dyeing can takes place at high temperature 135-150’ C. Jets are builds to be used at low liquor ratios between 10:1 and 5:1 and lower.

Advantages: -Less water, energy and chemicals; Shorter dyeing cycle time; Efficient and high production; Can be dyed delicate woven / Knits, textured and lightweight fabrics.

GARMENT DYEING

Dyeing of completed garments of non-tailored categories, such as sweaters swat shirts, hosiery and panty hoses. Tailored items like suits or dresses cannot be dyed as garments because the difference in shrinkage of the various components distort and misshape the article.

Garment dyeing is done by; placing suitable no. of garments (usually 24 sweaters or equivalent) into large nylon net bag. Loosely packed 10-50 bags are then placed in large dye bath and kept agitated by a motor driven paddle. “Paddle dyer”

Important features:

Less fashion risk, material need not be dyed until shortly before the actual sale of the merchandise; All fabric used in one garment must come from the same lot of fabric.

Fabric must be tested for shrinkage before cutting of garments, and must be given required tolerance to allow for shrinkage so that size will be accurate. Thread must be selected carefully and tested to be sure it will accept the dye in the same way as the fabric.

Labels, buttons and zippers must be compatible with the garment fabric in terms of reaction to the dye and shrinkage.

Stock dyeing

Yarn Package Dyeing Machine

Winch / Beck Dyeing machine

Jigger Dyeing Machine

HTHP Jet Dyeing machine

HTHP Soft flow Dyeing machine

Horizontal Padding machine for continuous dyeing

Vertical padding machine for continuous dyeing

DIRECT DYES:

- Derived from formulation of Benzedrine salts;

- Water soluble and Least expensive;

- Easy to apply, can be applied directly without pretreatment, fixing agents are not required; Used only for cellulose fibers;

- Wide range of colors and shades and not may bright colors; Among bright colors, only bright greens, but more expensive than other color.

- Good color fastness to perspiration/dry cleaning;

- Light fastness varies widely from poor to very good; some direct dyes are metalized with copper to increase their light fastness;

- In other cases, copper salts are applied as an after treatment for improving light/wash fastness.

- Poor fastness to washing and crocking;

- Used as back ground color for discharge printing

THE APPLICATION OF DIRECT DYES FOR CELLULOSIC MATERIALS.

In a typical exhaust dyeing the direct dyes are dissolved carefully, filtered or strained, and then added to the dye- bath. The cellulosic substrate is placed in the dye- bath at 49°C, and dyeing is continued at this temperature for 15- 20 minutes. Then common salt or glauber salt in the solid form is added portion- wise, over a period of 45-60 minutes, while the temperature is slowly raised to the maximum temperature of dyeing. Additions are made by starting with a small amount of salt followed by larger ones. For example, the salt to be added is divided into four portions: 1/8, 1/8, 1/4, and 1/2of the total amount.

The total amount of salt used is usually in the range of 5-25%, depending on the depth of shade, liquor ratio, and the type of direct dyes used. I the shade is satisfactory, the dyed material is then rinsed with cold water. At this stage an after – treatment may follow to improve the wash – fastness of the dyes.

After- Treatment of Direct Dyes

In a typical after- treatment the bath is prepared with the proper amount of the cationic fixing agent (e.g. 1-2% o.w.f. of the fixing agent for material dyeing with 1% of a direct dye), and a small amount of acetic acid (pH of bath: 5-6). The dyed material is placed in the bath, and treated at 49-54C(120- 130F) for 15-20 minutes. Then the treated material is rinsed with cold water and dried.

The light-fastness of some direct dyes can be improved by an after-treatment with copper sulfate. A small improvement in wash-fastness is also observed some product offered for after-treatment are mixtures of copper sulfate and a cationic fixing agent for the improvement of both light and wash-fastness. Because of harmful ecological effects, many transition metal compounds, including copper compounds, are subject to effluent discharge regulations.

Stripping Of Direct Dyes

A complete stripping in this case will consist of two steps: the dyed material is treated at the boil with a sequestering agent such as EDTA (e.g. 1-2g. / liter), after which the material is treated in a second bath with a reducing or an oxidizing agent.

REACTIVE DYES

- Reactive dyes are water soluble anionic dyes.

- Primarily used for cotton and other cellulose fiber at an alkaline pH of 9-12; Wool, silk and polyamide fibers are dyed in weak acidic dye baths.

- Procion-H type will react with cellulose in presence of sodium carbonate at the temperature range of 75-90°C;

- Procion- C type reacts at room temperature in presence of sodium carbonate.

- Ramazol (Vinyl sulfone reactive dye) will react in presence of base under goes and elimination reaction to form vinyl-sulfone group, which then combines with cellulose and time consuming process.

- Available in complete range of colors including very bright colors;

- Very good fastness to washing; Good-very good fastness to light; Good fastness to dry cleaning, perspiration, crocking;

- Poor fastness to chlorine bleaching;

- Easy to obtain level dyeing; High flexibility in the choice of method of application.

- Cost of using reactive dyeing is high, because Price, Loss of dyes during application and extensive washing; Excessive time required for the dyeing process.

THE APPLICATION OF REACTIVE DYES FOR CELLULOSIC MATERIALS

Applications of reactive dyes by batch dyeing consist of three stages:

- Exhaust dyeing

- Fixation, and

- After- scouring.

The following is a typical procedure for exhaust dyeing at a high temperature:

The dye bath temperature is set at 50°C, and the pre-dissolved reactive dyes are added. Then the substrate is placed into the dye-bath and the temperature is raised at 1C per min to 80°C (about 30 min). During this time the salt (e.g. 100% o.w.f., depending on liquor ratio and depth of shade) is added portion-wise. Dyeing continues at 80°C for an additional 15 min., after which sodium carbonate is added over 15 min.

The dyeing machine is run at 80°C for 45-75 min., during which time fixation is completed. The dyed material is given two more rinses, first with warm water followed by cold water, and then dried.

Continuous dyeing with reactive dyes – Two Bath Method

Dye/pad/dry/chemical-pad/steam

In this method, the dyes and the base are applied separately. The fabric is padded first with the dye solution containing the proper dyeing assistants, without the base. Included in the padding bath is an antimigrant to help prevent the dye solution moving from wet parts to dry parts on the impregnated fabric, during the following drying step.

After careful drying, the fabric is padded a second time with a solution containing the base and a large amount of salt. The presence of an electrolyte will prevent the dye from contaminating the chemical pad. Then, without drying, the fabric is introduced into a streamer (saturated steam at 102°C – 105°C) for 30-60 sec. The fabric is then thoroughly after-scoured by passing it through a range of several wash boxes, and dried or treated further with finishing agents.

Vat dyes

- Vat dyes are insoluble organic compounds and not substantive to cellulose.

- Widely used for cellulose fibers can be used for protein and nylon fibers.

- Produce good color range but limited selection of orange, blue and bright green. Large amount of dyes are required for deep shade.

- Excellent fastness to washing.

- Very good fastness to crocking, perspiration, chlorine bleaching, oxidizing and high temperature treatments.

- Expensive process: High initial cost of dye and method of application

THE APPLICATION OF VAT DYES FOR CELLULOSICS

The conventional exhaust method of vat dyeing procedure is carried out the following major steps:

- Reduction (vatting)

- Dyeing

- Oxidation

- Soap at boil

Application conditions for Various Types of Vat Dyes

(Approximate values for dyeing medium shades at a liquor ration of 1:10)

| TYPE | IN | IW | IK |

| C.I. method 1 | C.I. method 2 | C.I. method 3 | |

| Reduction Temp | 60°C | 49-54°C | 38-49°C |

| Dyeing Temp | 60°C | 44-49°C | 21-26°C |

| NaOH | 6-9 g/l | 3-5 g/l | 2.5-4 g/l |

| Hydrosulphite | 6-9 g/l | 4-6 g/l | 3-4.5 g/l |

| Salt | none | 7.5-15 g/l | 10-20 g/l |

IN – normal procedure IW – warm temperature

IK – cold temperature

1. Reduction (vatting)

At this stage, the vat dye is converted into its soluble form. The dye is first mixed with the proper amount of sodium hydroxide. Then the reducing agent is added, and the temperature is raised to the recommended temperature, time, and the amounts of reducing agent and base needed for specific dyes are shown in Table.

The reducing agents most commonly used are sodium hydrosulphite (Na2S2O4) and thiourea-dioxide. Hrdrosulphite will oxidize on exposure to air in presence of moisture or in solution. It is also very unstable at high temperatures, and therefore should be dissolved in cold water just before adding it to the dye-bath.

Thiourea-dioxide is much more expensive than sodium hydrosulphite, however, a much smaller quantity is needed to reduce the same amount of a vat dye. Thiourea-dioxide is also significantly easy to handle and more stable than sodium hydrosulphite, and is not affected by moisture.

The use of soft water throughout the dyeing process is must with vat dyes, since the soluble leuco salts will form insoluble salts with calcium or magnesium ions as well with transition metals. Therefore, in addition to using soft water, it is common to add sequestering agents such as EDTA to the dye bath.

Certain vat dyes may undergo over-reduction if reduction procedure is not followed carefully. The factors leading to over-reduction are

-

-

- Use of large amount of reduction agents

- Insufficient amount of NAOH in dye-bath

- Dyeing at higher temperature than recommended

-

Therefore, in application procedure it is recommended to add NAOH first, before the reducing agent.

2. Dyeing:

The scoured material is inserted in the dye-bath and the temperature is gradually raised to the dyeing temperature (27C to 60C(80F to 140F), depending on the type of dyes used). Dyeing continues for the proper amount of time and salt may be added to assist in exhaustion. Since atmospheric oxygen reacts with the reducing agent as well as with the reduced vat dyes, additional amounts of the reducing agent and the base are added during the dyeing stage. The dye-bath is checked occasionally to insure that the pH of the bath is sufficiently basic (phenolphthalein paper should turn red), and that a sufficient amount of the reducing agent is present in the dye-bath (yellow vat testing should turn blue).

3. Oxidation:

Before oxidation, the material is rinsed to remove residues of sodium hydroxide and reducing agent. Common oxidizing agents used today are hydrogen peroxide and sodium perborate. When using hydrogen peroxide, high concentrations of alkali must be avoided to prevent damages to fibers.

4. Soap at the boil

This step consists of treating the dyed material with soap at or near the boil for 10-20 min. Soap at the boil increases the wash fastness of the dyes and yields their final shade.

The dyeing procedure is then completed by rinsing with hot and cold water.

SOLUBLE VAT DYES

- They are vat dyes already in the reduced soluble from, and have the unique feature that they will not oxidize by merely exposing them to the air.

- These dyes offers only limited number of shades and this class of dye cannot give deep shades.

- They are even more expensive than vat dyes.

- The important feature of this dye is can be used for polyester blends, wool and silk blends through single bath in pale shades.

SULFUR DYES

- Derived from the formulation of compounds containing sulfur;

- Water insoluble – applied in exhaust dyeing; Water soluble – applied in continuous dyeing;

- Widely used for celluloses; Relatively easy way to dye cellulose’s with good-to-excellent washes and lights fastness at a low cost;

- Produces a complete rang of colors in “dull shade”; Poor light fastness in pastel shades;

- Mainly used for dyeing cellulose’s in black, brown, navy blue or olive, in medium to dark shades; Some yellows and blues are available but there is only one red and green dye.

- Good fastness to light, washing, dry cleaning and perspiration;

- Poor fastness to chlorine bleach;

- Sulfur dyed materials higher than normal room temperature/presence of moisture tends to oxidize form sulfur acids, then cause tendering to cellulose fabric.

APPLICATION OF SULFUR DYES FOR CELLULOSIC

Soluble sulfur dyes behave like direct dyes with high substantivity. They tend to exhaust at lower temperatures and at a higher rate. Salt is added carefully at the lower temperature. Then, the temperature is gradually raised to the maximum dyeing temperature to complete exhaustion.

A typical bath dyeing is carried out as follows:

The dye-bath is prepared by diluting the Soluble Sulfur Dye with the proper amount of water. A small amount of sodium polysulfide (e.g. 1-2 % o.w.f.) and a similar amount of a sequestering agent are added, and the fibers are introduced into the dye-bath at 50°C. Sodium chloride (20-30%) o.w.f.) is added portion –wise (e.g. 1/8, 1/8, 1/4, and 1/2 of the total amount) over a period of 20 min., while the temperature is gradually raised to the maximum dyeing temperature, usually in the range of 60-82°C. dyeing continues at this temperature for about 30 min. The fibers are then rinsed well with warm and hot water, oxidized, rinsed, soaped at 82°C, rinsed with a mild alkali solution, and dried.

AZOIC/NAPHTHOL DYES:

- Dyes are derived from aryl amides organic compounds; Insoluble in water;

- Primarily used for cellulose fibers; some times also used for polyester and triacetate to produce black shades;

- Produces full range of red colors and Orange brilliant yellow along with maroons, scarlet deep black and burgundies; Azoic dyes lack green and bright blue colors.

- Good color fastness to washing and dry cleaning;

- Poor-good fastness to light;

- Dark colors have poor fastness to crocking dyeing process is complexity and time consuming.

APPLICATION OF AZOIC DYES TO CELLULOSIC FIBERS

The application of azoic dyes, by exhaust or continuous processes, consists of the following major steps:

- Naphtholation – Application of the naphtholate

- Intermediate step – Removal of excess naphtholate from surface of fibers

- Coupling – Application of the diazonium salt to fibers

- After-treatment – Through cleaning and soaping of the dyed substrate.

1. Naphtholation

Paste the Naphthol with Turkey Red oil or sulfonated oil, and a small amount of water. Raise the temperature to ~85°C. Add the required amount of alkali in the form of a concentrated solution. Continue to heat for a few min., while stirring. And raise temperature to the boil if needed until a clear solution is obtained.

2. Intermediate step

The purpose of this step is to remove, from the fiber’s surface, as much of the naphtholate solution as possible in order to avoid crocking problems. This is done by centrifuging, squeezing, vacuum extraction, or other means of hydroextration.

3. Coupling

For the coupling to take place at a desirable rate, without affecting the stability of the naphtholate or the diazonium salt, a specific pH must be maintained for each combination used; usually it is in the range of pH 5-7. Many times a mixture of acetic acid and sodium acetate is added to the diazonium salt solution to act as a buffer and maintain a pH of about 5. The naphtholated substrate is immersed in the diazonium salt solution at room temperature for 15-20 min., during which time the coupling reaction is completed.

4. After-treatment

At this stage the dyed substrate undergoes a vigorous rinsing in order to:

- Remove unreacted starting materials,

- Remove dye attached to fibers’ surface, and

- Aggregate the dye molecules to improve wash-fastness and yield the final shade.

This step consists of treating the fibers at a high temperature or near the boil with a detergent, for 10 to 20 min. A slight change in shade may take place during this stage as the result of formation of aggregates.

.

Acid dyes

Dyes of organic acids that are attract and attached the color to the fiber; Available in the form of salts; Water-soluble and are applied in acid medium; Mainly used for wool and silk; Acrylic, nylon and spandex

Produces complete color range except bright red and greenish blue; Bright colors tend to bleed; Some colors have good colorfastness to light, dry cleaning and crocking; Some colors have poor fastness to washing

General trends in properties of Acid Dyes

| Acid Dye | Acid Leveling | Acid Milling | Natural Dyeing |

| Types of Acid | Strong

(2-4% H2SO4) (pH <3.5) |

Weak

(2-4% CH3COOH) (pH 3.5-5.5) |

Ammonium salt

(NH4)2 SO4 (pH 5.5-7) |

| Solubility | high—————————————————- > | low | |

| Substantively | low—————————————————— > | High | |

| Level Dyeing | very good——————————————— > | fair | |

| Rate of Exhaustion | Slow—————————————————- > | fast | |

| Dyeing Time | relatively short—————————————-> | longer time | |

| Wet – Fastness | fair——————————————————–> | very good | |

| Color – range | wide range bright colors—————————-> | moderate brightness | |

The Application of Acid Dyes to Wool

Dyeing Procedure for Acid Leveling dyes

Exhaust dyeing is the method of choice for dyeing wool and it is carries out at different stages of production: raw stock (loose fibers), slubbing, yarn, or finished garments.

The following is a general Acid levelling dyeing procedure for wool:

- The dye – bath is prepared at 49ºC, in addition to the acid dyes, an acid (e.g. 2% H2SO4 o.w.f) or other acidic chemicals are added as required, to obtain the proper pH of the bath.

- Sodium sulfate (glauber salt: Na2SO4, 10% o.w.f) or other dyeing assistants are added as leveling agents.

- The dyeing machine is run for 5-10 min., after which the wetted material (raw stock, yarn, or fabric) is inserted.

- The dye bath temperature is gradually raised (1º per min) to the boil while agitating the material and/or circulating the dye solution through the material.

- Dyeing is carried out for 40-60 min., after which the dyed material is rinsed with cold water and dried.

Dyeing Procedure for Acid Milling Dyes:

- The dye – bath is prepared at 49ºC, in addition to the acid dyes, an acid (e.g. 1-3% acetic acid o.w.f) or other acidic chemicals are added as required, to obtain the proper pH of the bath.

- Sodium sulfate (glauber salt: Na2SO4, 0-10% o.w.f) or other dyeing assistants are added as leveling agent

- The dyeing machine is run for 5-10 min., after which the wetted material (raw stock, yarn, or fabric) is inserted.

- The dye bath temperature is gradually raised (1º per min) to the boil while agitating the material and/or circulating the dye solution through the material.

- Dyeing is carried out for 40-60 min., after which the dyed material is rinsed with cold water and dried.

Dyeing Procedure for Neutral Dyeing Acid Dyes

- The material is entered at 60C in a dye bath containing 2-5% ammonium acetate (or sulphate),

- The temperature is raised at the boil and dyeing continued at the boil for 45 minutes.

- No gloubers salt is used in this method.

- Neural dyeing acid dyes possess good fastness to washing.

Chrome / mordant / metallic dyes

Metallic salt of cobalt’s, aluminum or copper are added to dye molecules for fixing dyes; Water soluble and are applied with acid medium; Time consuming dyeing process; Dyes are applied in fiber, yarn or fabric form; Effective on wool & silk where maximum wet fastness is required; Acrylic, nylon, polyester and spandex considered secondary importance

Excellent fastness to perspiration/washing; Good fastness to light and dry cleaning; Very good fastness to crocking

Premetallized Acid Dyes (Metal Complex Dyes)

- The next step in the development of acid dyes with superior wash fastness has been the incorporation of a transition metal ion in the dye molecule by the dye manufacturers.

- These dyes usually contain a Cr³+ ion (some contain a cobalt ion) bonded to one (1:1 complex) or two (2:1 complex) dye molecules by ionic and coordinate bonds. Example of thee dyes are C.I. Acid Blue 158 (1:1 complex), and C.I Acid black 60 (2:1 complex).

- The 1:1 metallized dyes are available in a wide range of colors of moderate brightness. The 1:1 metallized dyes are easy to dissolve, and have good leveling properties.

- Their main disadvantage, however, is that they require a large amount of acid (approximately 8% H2SO4, pH 2) for exhaustion. This strong acidity may cause damage to the wool.

- The 2:1 metallized dyes, because of their large molecular size, behave similarly to the natural dyeing acid dyes.

- The 2:1 metallized dyes are noticed for their very good wash-fastness and light fastness.

- Another advantage of these dyes is that when using several different colors in the same bath they tend to exhaust at the same rate, and to the same extent.

- The main disadvantages of the 2:1 metal dyes are the lack of bright shades, high cost, and poor migration.

Application of 2:1 Metal- complex dyes for wool fibres

- The material is pretreated for 10 minutes at 40C in a bath containing 2-4% ammonium acetate or ammonium sulphate to obtain the pH range of 6-7 during dyeing.

- The pre dissolved dye solution is then added and the temperature raised to boil in 45 minutes.

- After dyeing for 30-60 minutes at boil the material is rinsed with cold water and then dried.

APPLICATION OF CHROME DYES FOR WOOL FIBRES

- These dyes also called mordant dyes have been used on protein fibers where maximum wet fastness is required.

- Chrome dyes can be applied separately with the chrome compound, and the end result of the dyeing process is the formation of a DYE – CHROME – FIBER complex.

- Chromium can attach to the dye and the fiber simultaneously by ionic and/or coordinate bonds. The chrome compounds used are usually sodium dichromate (Na2Cr2O7) or potassium dichromate

Chrome dyes can be applied by the fallowing methods:

- Bottom Chrome (Chrome Mordant Method):

- The chrome compound (potassium dichromate) applied first which, in a separate bath and dyeing with the chrome takes place.

- Top Chrome or after chrome:

- The dyes (chrome dyes) are applied first by one of the method used for regular acid dyes. Then the chrome compound is applied as an after treatment. The chrome compound can be applied from the same dye bath or from a new bath.

- Meta Chrome:

- Both the chrome compound and the chrome dyes are applied from the same bath.

Of these three methods the first two are now of historical value. The Top chrome method is being used, however, to a large extent, when dull colors with excellent wash fastness are desired.

The following is a typical application of chrome dye the Top chrome method:

- The dye bath is prepared with the proper amounts of an acid (Sulphuric acid or acetic acid) and sodium sulfate, and the chrome dyes.

- The fibers are introduced and the dye bath temperature is raised to the boil in 30-45 min. Dyeing continues at the boil for additional 30-45 min. During this time a small amount of acid is added if needed to complete the exhaustion.

- Then the dye-bath temperature is dropped to 71ºC by removing the part of the dye solution and replacing it by the same amount cold water.

- Then the proper amount of a solution of the chrome compound is added (e.g. for 1% Dyeing, 0.5% Sodium dichromate is used). The temperature of the bath is raised again and kept at the boil for 30-60 min. the treatment is completed by rinsing and drying.

- In addition to there excellent wash and crock fastness, chrome dyes have very good light fastness, and very good migration properties.

- The main disadvantage of the chrome dyes is that during complexing with the chrome a change in hue takes place. Since the color change takes place when the dye becomes firmly attached to the fiber, color matching in this method is difficult.

- Other disadvantages associated with the Top chrome method are the dulling effect of the chrome on the original color, the length time of the dyeing procedure, and the toxicity of the chrome compounds

APPLICATION OF ACID DYES TO SILK FIBERS

-

- Many acid dyes have excellent affinity for silk under neutral conditions and exhaust well at temperature below the boil.

- They are the most widely used class of dyes on silk combining brilliancy of shades and good color fastness performance with simplicity of application.

- Boiled – off liquor is often used for dyeing. It acts as leveling agent and keeps the silk soft and lustrous.

- The dye bath is set with 100 -500 ml per liter boiled – off liquor and made slightly acidic with acetic or formic acid.

- The material is entered at 50C and run for 15 minutes before adding the previously dissolved dyestuff.

- The dyestuff is added in portion wise and the temperature of the dye bath is raised gradually to 90C and the bath is maintained this temperature for 30 -60 minutes until the dyeing is completed.

- After dyeing, the silk is rinsed and brightened by working in a dilute solution of acetic acid, squeezed well and dried.

- In piece dyeing, 10 -20 % glauber salt and 1-3 % sulphuric acid are added to the dye bath.

APPLICATION OF METAL-COMPLEX DYES TO SILK FIBERS

- 1:2 metal complex dyes are mainly used for silk dyeing.

- The dyestuff is pasted with cold water, then sufficient hot water is added and the solution is boiled to dissolve the dye completely.

- The material is entered into a cold bath containing 1 -2 % leveling agent,2-4 % ammonium acetate or ammonium silhotte or 1 -2 % acetic acid ( 40 % ) at pH 4 -5.

- The dissolved dyestuff is then added and the temperature of the bath raised to 90-95C within 30-45 minutes and dyeing is continued at this temperature for 30 minutes.

- The material is taken out, washed, squeezed and dried.

- These dyes gives overall good color fastness performance and also exhibit very good fastness to light in pastel shades compared with chrome dyes. This method of dyeing is widely used to silk in all forms.

APPLICATION OF CHROME / MODRANT DYES TO SILK FIBERS

- Mordant dyes are rarely used on silk except logwood black.

- The silk is first steeped in a solution of cutch or myrabolan extract at 50–60 C and then steeped in a solution of pyrolignite of iron at 60 – 70C.

- It is then squeezed and exposed to air for 1-2 hours and washed.

- By this treatment the weight of the silk is increased by 20 -30 %

Disperse dyes

Non-ionic aromatic compounds with relatively low molecular weight, and has an extremely low solubility in water; Available n the form of powders, granular, liquid or paste; Sublimation takes place at high temperature; Dyeing is carried out high temperature/pressure; Can be used for heat transfer printing; Effective in polyester, Acetate, Tri Acetate; Can be used for nylon/acrylic and other synthetic fibers.

Produces good color range except dark blue and black; Good-excellent fastness to perspiration, crocking and dry cleaning; Fair-Good fastness to light and washing; when used on acetate poor fastness to light and subject to gas fading

APPLICATION OF DISPERSE DYES TO NYLON FIBERS

- Disperse dyes are the most suitable for nylon on account of their ease application and uniform levelness. They are primarily used for producing pastel to medium shades.

- One of the main problems associated with dyeing nylon with disperse dyes is unlevel dyeing which results from irregularities in fibre, and is referred to as ‘barre’. This type of unlevelness shows up as lighter or darker streaks or stripes on woven or knitted fabrics extending crosswise. Barre results from physical and chemical variation in nylon fibres.

- In typical dyeing procedure, the bath is prepared with the disperse dyes and a dispersing agent, and the pH is adjusted to 5-6 with acetic acid.

- The nylon material is inserted and the dye-bath temperature is gradually raised to 88-93C.

- Dyeing continues at maximum temperature for about 60 minutes, after which the material is rinsed and dried.

- One of the main problems associated with dyeing nylon with disperse dyes is unlevel dyeing which results from irregularities in fibre, and is referred to as ‘barre’. This type of unlevelness shows up as lighter or darker streaks or stripes on woven or knitted fabrics extending crosswise. Barre results from physical and chemical variation in nylon fibres.

APPLICATION OF DISPERSE DYES TO POLYESTER FIBERS

- Dyeing of polyester with disperse dyes at the boil for a reasonable length of time will produce only very pale shades.

- The compact structure of polyester does not open up well when immersed in boiling water, and more vigorous conditions are required for proper dyeing to takes place.

- Good results with disperse dyes are obtained when dyeing by one of the following methods:

- By using selected disperse dyes having very small molecular size which can readily diffuse in to the fibres.

- Atmospheric dyeing with dye-carriers

- High temperature & High pressure dyeing

- Continuous dyeing by the thermosol process

Atmospheric dyeing with dye-carriers

- Certain chemical called carriers are added to the dye bath; they swell the fibres at boil to relax the spaces between inner molecular structures of the fibre to accommodate the dye particles.

- The swollen fibre structure is helps large dye m molecules to diffuse more rapidly in the fibre.some of chemicals are used as carriers are ophenol; pophenol di-chloro benzene- tri-chloro benzene.

- The carrier is usually added slowly during the dyeing process because if it is added at once, the dyestuff may rush on to the material.

ATMOSPHERIC PRESSURE

- Only a small percentage of the polyester fibres in the use is currently dyed by this method, since it requires the use of large amounts of the undesirable dye-carriers.

- Dyeing at temperature as high as 135oC(275oF) is possible with new dyeing equipment that can withstand high pressures.

- Under these conditions better diffusion and dye-fastness are obtained without using dye-carriers.

PRESSURE DYEING

- Best results with exhaust dyeing are obtained when carried out at temperatures in the range of 130oC. Dyeing under these conditions gives:

- Good overall fastness (wash fastness,crocking,etc.)

- Particularly good leveling results,

- The opportunity to eliminate completely the use of dye-carriers with their associated unpleasant properties,and

- The possibility of using a wider range of disperse dyes, and a better coverage of barre.

- Dyeing under pressure at lower temperatures (e.g. 115oC) is not recommended.

- It should only be used when the equipment is not capable of handling the pressure at 135oC .

- However for pastel shades lower temperatures(115oC or even atmospheric dyeing) may be considered.

- A small amount of a dye-carrier is some times used for leveling purposes.

RAPID DYEING UNDER PRESURE

Rapid dyeing is only possible with machines that can operate under the following condition

- Low liquor ratios ( approx. 1:7 to 1: 10 )

- Uniform bath temperature thought

- High dye-bath circulation and/or fast movement of fabric

The following is a typical example of rapid dyeing of 100 % polyester knit that has been heat set and that has been going to be scoured before dyeing;

- Scour with a non ionic surfactant ( 1-2 g/l ) and sodium carbonate ( 1-1.5 g/l ) at 65-70 C for 15-20 minutes, then rinse with a small amount of acetic acid

- Set the bath temperature at 50C and add

-

- 0.5 – 1 % anionic dispersing agent

- 0.25 % sequestering agent ( EDTA )

- 0 – 2 % dye carrier

- acetic acid to pH 4.5 – 5

-

- Run the bath for 5 – 10 minutes and check Ph

- Add required % of pre-dispersed dyes slowly

- Run the bath for 5 – 10 minutes and check Ph

- Heat as rapidly as possible to 70C

- Heat 70 -82C at the rate of 2C per minute

- Heat from 82C to 130C at the rate of 1.5C per minute

- Dye at 130C for 20 minutes

- Cool down the bath to 82C and rinse

- After-scour ( not needed for light to medium shades )

- -Reduction Clearing-

- set bath at 50C

- add 2% sodium carbonate

- raise the temperature to 77C

- add 2-3% sodium hydrosulfide

- run at 77-82C for 15-20 minutes

- Rinse with hot water

- Neutralize with acetic acid at 50C

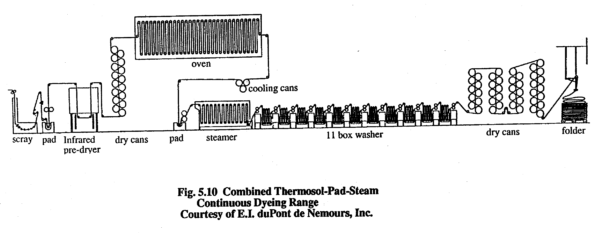

Continuous dyeing by the Thermosol Process

The application is carried out continuously and consists of padding the polyester fabric with dispese dyes, drying, and then placing the fabric in a curing oven at 200-210C for less than one minute, during which time the dyes diffuse and dissolve in the polyester. The padding bath contains in addition to the dyes, acetic acid (pH 4.5-5.5 ) and a wetting agent(1-3 g/l ). A dispersing agent is added only if necessary. During the thermosol stage disperse dyes move into the polyester fibres through sublimation.

Basic dyes

Dyes are derived from salts of tri phenyl methane derivatives; Water-soluble and contains cationic group; Mainly used for acrylic/mod acrylics; Can be effective for wool and silk but poor fastness properties; Also being used for nylon, polyester and cotton.

Produces complete range of bright colors; Good color fastness to light, washing perspiration and crocking for acrylic and mod acrylic; Very poor fastness to washing and light on cotton, wool and silk

APPLICATION OF BASIC DYES TO ACRYLIC FIBERS

- Acrylic fibres are almost always dyed with basic dyes that yield with wash and light fastness.

- The following is a typical procedure for dyeing a medium shade on a 100% acrylic knit with basic dyes.

- The dye bath is prepared with dyeing assistants at 50C.

- Acidic acid is added to obtain a pH of 4.5-5 and sodium sulfate (5-10% o.w.f) and a cationic retarder (1-2% o.w.f) are added as leveling agents.

- The fabric is entered and the bath is run for 5 minutes. Then the dissolved cationic dyes are added slowly over a period of 10 minutes.

- After which the temperature is raised at 1C per min. to just below the glass transition temperature (anywhere between 68-85C) of the fibre.

- Dyeing temperature is kept at this point for 15 minutes, after which it is raised to the boil. Then the dyeing continues at the boil for about 1 hour.

- When proper shade is obtained, the dye bath is cooled very slowly to about 10C below the glass transition temperature (to avoid the formation of creases), and then dropped. The dyeing is completed by rinsing.

PIGMENT DYEING

The pigment consists of binder (film forming compound acts as adhesive). Usually this binder reacts at a temperature of 140°C to 150°C. Use of catalyst (Fixer CCL) brings down the temperature to 100°C to 110° C. There are two types of binders are commonly used (i) puff binder, (ii) peal binder (gives silver finish).

Formulation of recipe for dyeing with pigment

Pigment – to taste

Binder – 10 – 20 g/l

Catalyst – 0.5 – 1 g/l

Acetic acid – 2 – 3 g/l

Make a paste with all ingredients

Pad with 70% pick up

Dry (100°C)

Cure (150°C, 2-3 min)

IMPERFECTIONS OF DYED FABRICS

These imperfections may be due to improper; Dyeing procedure, Preparation of the fabrics prior to dyeing, Imperfection in the material itself

Bare

In woven fabrics, horizontal bands of off shaded yarns are extending from selvedge of selvedge. Caused by differences in weft yarn count or variations in tension of warp and weft yarns.

Color crocking

Color in a dyed fabric, which rubs off rather easily onto other fabric surfaces. May be caused by in adequate washing at the completion of dyeing process.

Color bleeding

Loss of color in a dyed fabric during washing or dry cleaning due to un bonded dyes

Off shade

An expression referring to the fact that the color of the dyed fabric does not match the standard color or referenced color.

Shade bar

A shade change in a fabric that appears as a horizontal bar from selvedge to selvedge. Caused by a weft package change and loom stop start-up during weaving.

Stained cross dye

In cross dyeing, usually of one color and white, where the dye of the colored portion stains the white portion.

In solid colored fabric, the term refers to specks of foreign matter that have been caught in the material and do not become dyed.

Tender spots

Places in fabrics that have been excessively weakened, usually by exposure to processing chemicals.